We are a national high-tech enterprise. At present, there are many kinds of self-woven and cooperatively processed fabrics, including microfiber warp-knitted towel cloth, weft-knitted towel cloth, coral fleece, etc.

Imagine elevating a simple tote bag with a beautifully patterned handle, adding a pop of branded color to a garment's trim, or creating a unique, comfortable collar for a beloved pet. This transformative power lies in decorative jacquard webbing straps. These are not just functional straps; they are intricate, woven fabric bands featuring permanent, raised patterns directly integrated into their structure through specialized looms. They serve as a critical junction where durability meets high-end design, offering a tactile and visual upgrade over plain or printed webbings. For designers, brands, and manufacturers, selecting the right webbing involves navigating questions of material science, aesthetic alignment, and technical specifications. How does the jacquard weaving process differ from standard methods? What materials are best suited for a handbag versus activewear? The journey from a creative concept to a bulk roll of custom webbing requires partnership with an experienced producer. With over two decades of specialization in weaving technology, our operations are built on a foundation of strict quality control and a dedicated technical team. Guided by the principle of "Quality and Innovation in Equal Measure," we focus on transforming client ideas into tangible products, from woven label jacquard webbing for bags to colorful jacquard webbing for clothing trim, ensuring each batch meets exacting standards for performance and appearance.

- 1 Unraveling the Craft: The Anatomy of Jacquard Webbing

- 2 Definitive Applications and Selection Strategy

- 3 From Concept to Creation: The Custom Manufacturing Journey

- 4 FAQ

- 4.1 What is the typical Minimum Order Quantity (MOQ) for custom jacquard webbing?

- 4.2 How long does sampling take, and is there a cost involved?

- 4.3 What are the main durability differences between polyester and cotton jacquard webbing?

- 4.4 How can I ensure the woven colors match my brand's Pantone references?

- 4.5 Are these webbings eco-friendly, and what certifications are available?

Unraveling the Craft: The Anatomy of Jacquard Webbing

To truly appreciate and specify decorative jacquard webbing straps, one must understand the core elements that define their quality, appearance, and performance. The distinction begins with the weaving process itself. Unlike simple plain or satin weaves, jacquard weaving utilizes a mechanical or electronic mechanism to individually control hundreds of warp yarns. This allows for the creation of complex, detailed patterns—logos, geometric designs, text—that are structurally woven into the fabric, not merely printed on the surface. This results in a durable, textured pattern that is resistant to wear and peeling. The choice of material then dictates the strap's fundamental character: its strength, hand feel, elasticity, and suitability for different environments. Finally, the design dimensions—width, color palette, and pattern complexity—open a world of customization possibilities, directly impacting the final application. Mastery of these three pillars is what separates standard webbing from exceptional, purpose-built custom woven jacquard webbing straps.

- The Jacquard Mechanism: This is the heart of the process. Historically using punch cards and now often computer-controlled, it allows each warp thread to be raised or lowered independently, creating intricate, non-repeating patterns with a pronounced, textured feel that is integral to the webbing.

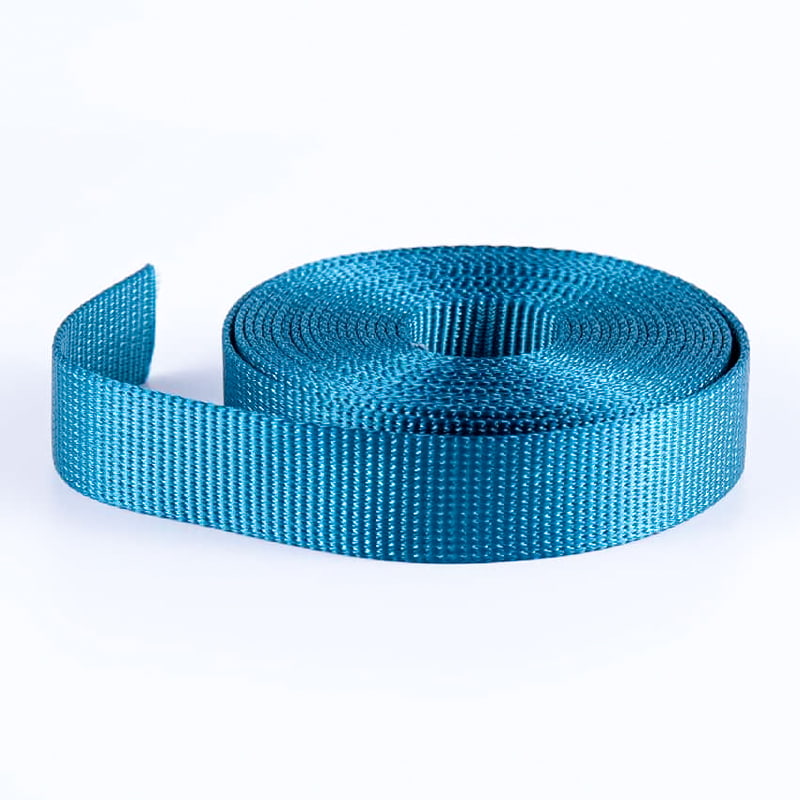

- Material Science in Practice: Our production leverages a range of materials to meet diverse needs. Polypropylene offers cost-effectiveness and color variety, while polyester is prized for its high tensile strength, excellent colorfastness, and resistance to moisture and mildew, making it ideal for items like polyester jacquard webbing for pet collars. Nylon provides superior elasticity and abrasion resistance, and cotton delivers a natural, soft hand feel valued in certain apparel and accessory lines.

- Design Flexibility: Specifications are highly adaptable. Width can range from narrow trim to extra wide decorative jacquard webbing for statement furniture accents. The color range is vast, achieved through solution-dyed yarns for maximum fade resistance or yarn-dyed processes for multi-colored patterns. Custom patterns are developed directly from client-provided artwork or samples.

Material Comparison Guide for Common Applications

| Primary Material | Key Properties | Ideal Application Examples | Considerations |

| Polyester | High strength, excellent UV & mildew resistance, low stretch, good color retention. | Outdoor gear, bag straps, pet products, woven label jacquard webbing for bags. | The industry standard for durability; less elastic than nylon. |

| Nylon | High elasticity, exceptional abrasion resistance, soft hand feel, strong. | Technical apparel, adjustable straps, equipment lanyards. | Can absorb moisture; may degrade with prolonged UV exposure unless treated. |

| Cotton | Natural, breathable, biodegradable, soft texture, eco-friendly appeal. | High-end garment trim, artisanal crafts, home decor accents. | Less resistant to moisture and mildew; may shrink if not pre-shrunk. |

| Polypropylene (PP) | Lightweight, water-resistant, cost-effective, good color brightness. | Promotional items, indoor decorative straps, lightweight packaging. | Lower melting point; not suitable for high-heat or heavy-load applications. |

Definitive Applications and Selection Strategy

The true value of decorative jacquard webbing straps is realized in their application. Each use case presents unique demands for strength, aesthetics, and compliance. A successful project hinges on matching the webbing's engineered properties to the product's functional and brand requirements. For instance, a strap serving as a bag's primary handle must withstand significant weight and friction, while a trim on a baby garment demands supreme softness and safety compliance. Whether the goal is to create a distinctive brand identifier, add a functional yet fashionable element to apparel, ensure safety and style for pets, or achieve a bold decorative statement, a strategic selection process is essential. The following sections provide a detailed roadmap for navigating these key application areas, helping you specify the perfect webbing for your next project.

Branding Redefined: Woven Label Jacquard Webbing for Bags

In the competitive accessories market, brand differentiation is paramount. Woven label jacquard webbing for bags offers a premium alternative to leather patches or printed labels. By weaving a logo, brand name, or signature pattern directly into the strap or a dedicated label strip, you create a durable, tactile brand mark that withstands the rigors of daily use. This application goes beyond mere labels; it extends to functional bag handles, crossbody straps, and decorative accents. The webbing must combine visual appeal with structural integrity, requiring high tensile strength, excellent abrasion resistance, and precise color matching to maintain brand consistency across production runs.

- Durability is Key: Specify high-density polyester or nylon webbing for main load-bearing straps to ensure they can handle weight without stretching or fraying.

- Pattern Precision: The jacquard process allows for crisp, detailed logos. Provide high-contrast, vector-based artwork for the best results in sampling and production.

- Integrated Design: Consider using the branded webbing as both a structural and decorative element, such as a uniquely patterned handle that becomes the bag's signature feature.

Fashion's Functional Detail: Colorful Jacquard Webbing for Clothing Trim

Apparel designers constantly seek innovative ways to add detail, color, and texture. Colorful jacquard webbing for clothing trim serves as a versatile tool for this purpose. It can be applied as a striking neckline trim, a contrasting sleeve cuff, a defined waistband, or as creative piping and seam detailing. The choice of material here is crucial for comfort and care; it must be soft against the skin, have minimal shrinkage to match the garment's behavior, and withstand repeated washing. The visual impact comes from the interplay of colors and patterns woven directly into the trim, offering a luxury feel that printed trims cannot replicate.

- Softness and Drape: For direct skin contact, consider cotton blends or fine, soft-finished polyester webbings that drape well and avoid stiffness.

- Colorfastness: Ensure the webbing is tested for colorfastness to washing, perspiration, and rubbing to prevent dye transfer onto the main garment fabric.

- Application Techniques: This trim can be topstitched, inserted into seams, or used as a binding, offering numerous design possibilities from sporty to haute couture.

Companion Style and Safety: Polyester Jacquard Webbing for Pet Collars

Pet products require a careful balance of safety, comfort, and style. Polyester jacquard webbing for pet collars is the dominant choice for these reasons. Polyester offers the necessary strength to withstand pulling, excellent resistance to dirt and moisture (easily wiped clean), and superior color retention through outdoor exposure and frequent washing. The jacquard process allows for the weaving of fun patterns, pet names, or owner contact information directly into the collar, creating a personalized and durable product. Safety considerations include the use of non-toxic dyes and robust stitching points for buckles and D-rings.

- Strength and Security: A high-weight, dense weave is non-negotiable for safety. The webbing must maintain its integrity under stress.

- Easy-Clean Features: Polyester's low moisture absorption makes it quick-drying and resistant to odor-causing bacteria, ideal for an active pet.

- Personalization Trend: The market increasingly values custom-woven pet names or icons, turning a functional item into a unique accessory.

Bold Statements and Versatile Uses: Extra Wide Decorative Jacquard Webbing

When a narrow trim won't suffice, extra wide decorative jacquard webbing makes a dramatic impact. This format transforms the webbing from an accent piece into a primary design element. In home furnishings, it can be used as a striking bolster tie on a sofa, a decorative border on curtains, or as a woven panel in itself. In creative industries, it finds use in theatrical costumes, high-end gift wrapping, and statement accessories. The wider format allows for larger, more complex pattern repeats and creates a substantial visual and tactile presence that commands attention.

- Structural Support: Wider webbing often requires a stable, non-stretch construction to lay flat and maintain its shape, often calling for a tight polyester or cotton weave.

- Design Scale: The pattern design must be scaled appropriately for the width to ensure visual clarity and impact.

- Versatile Attachment: Applications range from being stitched onto surfaces to being used as a freestanding strap or belt, requiring consideration of finishing on the cut edges, such as hemming or sealing.

From Concept to Creation: The Custom Manufacturing Journey

Embarking on a project requiring custom woven jacquard webbing straps is a collaborative process between your vision and the manufacturer's expertise. A transparent and efficient workflow is critical to achieving a result that matches your specifications in quality, aesthetics, and timeline. This journey typically begins with a detailed brief—whether a digital design file, a Pantone color code, or a physical sample—and progresses through technical review, sampling, and finally, production. Partnering with a manufacturer that operates under a robust management system and views quality control as integral at every stage mitigates risk and ensures consistency. The principles of reliable quality, competitive pricing, and on-time delivery are not just promises but the outcome of a mature, integrated production philosophy focused on continuous improvement of both product and process.

- Phase 1: Design Consultation & Technical Review: This initial stage involves analyzing your design for weave feasibility, recommending optimal materials (e.g., polyester for a polyester jacquard webbing for pet collars project), and confirming specifications like width, thickness, and color method. Clear communication here sets the foundation for success.

- Phase 2: Sampling & Approval: A physical sample or "strike-off" is produced for your approval. This critical step allows you to verify the hand feel, color accuracy under different lights, pattern clarity, and overall quality before committing to mass production.

- Phase 3: Production & Quality Assurance: Upon sample approval, bulk production begins under monitored conditions. In-line quality checks monitor weaving consistency, color matching, and strength. Final inspection before shipment ensures the entire order meets the agreed standard.

- The Manufacturer's Role: An established manufacturer contributes more than just machinery. A strong technical team solves potential issues proactively, modern equipment ensures precision and efficiency, and a commitment to innovation helps translate even complex creative concepts into producible woven reality.

FAQ

What is the typical Minimum Order Quantity (MOQ) for custom jacquard webbing?

Minimum Order Quantities are a standard practice in textile manufacturing due to the setup involved in threading looms with specific yarns and programming custom patterns. MOQs can vary significantly based on the complexity of the design, the material selected, and the manufacturer's capabilities. For simpler, stock-colored patterns using existing yarns, MOQs might start in the range of 500 to 1,000 meters. For highly complex, multi-color custom woven jacquard webbing straps requiring new yarn dyes and extensive loom setup, the MOQ will be higher to make the production run economically viable. It's always best to discuss your specific project requirements directly with the manufacturer to get an accurate MOQ quote, as some may offer more flexibility for new partnerships or particularly innovative designs.

How long does sampling take, and is there a cost involved?

The sampling process is a crucial investment in your project's success. The timeline for receiving a first sample typically ranges from 2 to 4 weeks after finalizing design and material details. This period includes yarn sourcing or dyeing (if custom colors are needed), loom setup, and the actual weaving of the sample piece. Most manufacturers charge a sampling fee, which covers these setup costs and the dedicated machine time away from standard production. This fee is often credited against your eventual bulk order. Providing clear, high-resolution artwork and detailed specifications from the outset can help minimize back-and-forth and accelerate the sampling phase, ensuring your vision for a woven label jacquard webbing for bags or colorful jacquard webbing for clothing trim is accurately realized on the first attempt.

What are the main durability differences between polyester and cotton jacquard webbing?

The choice between polyester and cotton fundamentally impacts the longevity and care of the final product. Polyester is a synthetic fiber renowned for its high tensile strength, excellent resistance to abrasion, mildew, and UV fading, and minimal shrinkage. It is the go-to material for high-stress, outdoor, or frequent-wash applications like bag straps, pet gear, and performance apparel trim. Cotton, a natural fiber, offers superior softness, breathability, and a classic aesthetic. However, it is generally less strong than polyester, can shrink if not pre-shrunk, and is more susceptible to mildew and fading when exposed to moisture and sunlight over time. For a durable polyester jacquard webbing for pet collars, polyester is unequivocally recommended. For a soft, natural-feeling decorative jacquard webbing straps on a high-end indoor cushion, cotton may be the perfect choice.

How can I ensure the woven colors match my brand's Pantone references?

Accurate color matching is a top priority in custom weaving. The process begins with you providing specific Pantone Matching System (PMS) codes for each color in your design. Reputable manufacturers will then create "lab-dips" or "yarn-dips." These are small samples of the actual yarn dyed to match your Pantone references under standardized lighting conditions. You will approve these dyed yarns before they are loaded on the loom for sampling. It's important to understand that the final woven color can appear slightly different than a solid yarn dip due to the optical mixing of warp and weft threads in the weave structure. Evaluating the color on the actual woven sample, rather than just the yarn, is the definitive step. Professional manufacturers with strong technical teams are experienced in managing these subtleties to achieve the closest possible match for your custom woven jacquard webbing straps.

Are these webbings eco-friendly, and what certifications are available?

Sustainability is an increasingly important consideration. The eco-friendliness of decorative jacquard webbing straps depends primarily on the base material and the dyeing processes used. Options include using recycled polyester (rPET) made from post-consumer plastic, organic cotton grown without harmful pesticides, or other bio-based fibers. Additionally, manufacturers can employ eco-friendly dyeing methods that reduce water and chemical usage. Certifications provide verified proof of these claims. Common ones to look for include the Global Recycled Standard (GRS) for recycled content, OEKO-TEX Standard 100 which tests for harmful substances (crucial for products like polyester jacquard webbing for pet collars), and certifications for organic cotton. When inquiring about custom webbing, clearly express your sustainability requirements so the manufacturer can advise on suitable material choices and available certifications for your specific order.

Title: Custom Decorative Jacquard Webbing Straps Guide & Uses Description: Explore decorative jacquard webbing straps: custom design, materials (polyester, cotton), and uses for bags, apparel, pet collars. Learn selection & manufacturing. Keywords: jacquard webbing, custom woven straps, decorative webbing URL slug: decorative-jacquard-webbing-straps-guide

English

English  中文简体

中文简体