We are a national high-tech enterprise. At present, there are many kinds of self-woven and cooperatively processed fabrics, including microfiber warp-knitted towel cloth, weft-knitted towel cloth, coral fleece, etc.

- 1 Introduction: The Engineered Component in Modern Supply Chains

- 2 Part 1: Material Foundation – The Polymer Science of Polyester

- 3 Part 2: Decoding Specifications – The Language of Professional Procurement

- 4 Part 3: Application Engineering – Matching Webbing to Critical Use Cases

- 5 Part 4: Strategic Sourcing – Partnering with a Professional Manufacturer

- 6 Conclusion: Building Product Integrity from the Component Up

- 7 Frequently Asked Questions (FAQs)

- 7.1 1. For a safety-critical lifting application, what documentation is mandatory from the webbing manufacturer?

- 7.2 2. How can I verify claims of "UV resistance" for outdoor furniture webbing?

- 7.3 3. What is the practical difference between a standard and a "high-tenacity" polyester webbing?

- 7.4 4. What are the key factors affecting the cost of a custom printed webbing strap?

- 7.5 5. Why is polyester often recommended over nylon for long-term static tie-down applications?

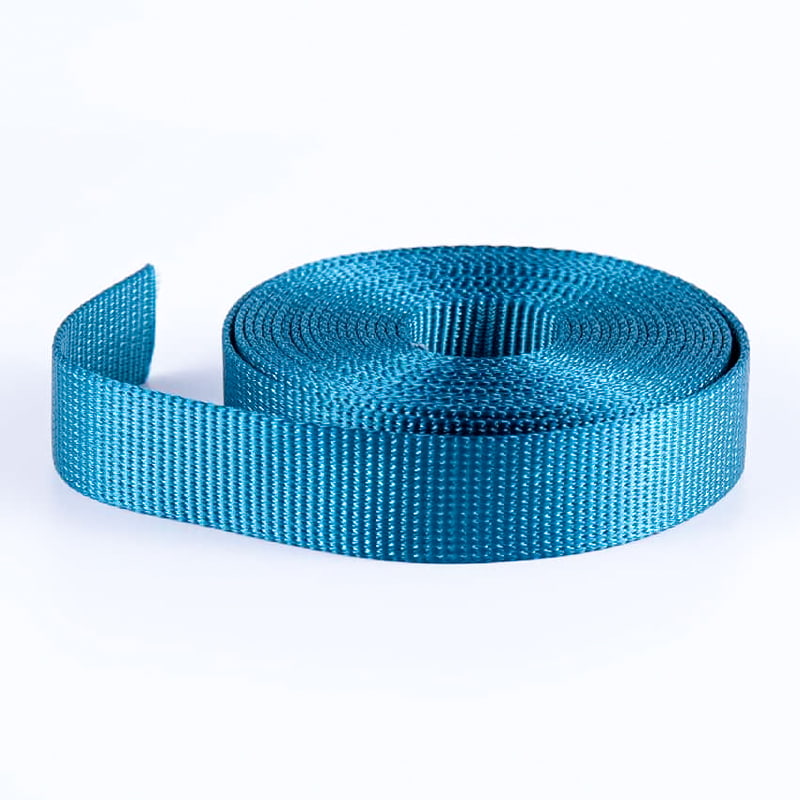

Introduction: The Engineered Component in Modern Supply Chains

In industrial design and manufacturing, a polyester webbing strap is rarely just a piece of fabric. It is a critical load-bearing, safety, or interface component whose performance is dictated by polymer science, mechanical engineering, and rigorous quality standards. For procurement specialists, engineers, and product designers, selecting the right webbing is a technical decision with direct implications for product integrity, user safety, and compliance. This guide provides a deep dive into the engineering rationale behind polyester webbing, decodes industry specifications, and outlines a framework for strategic sourcing from professional manufacturers.

Part 1: Material Foundation – The Polymer Science of Polyester

1.1 Molecular Advantages of Polyethylene Terephthalate (PET)

The superior properties of polyester webbing strap originate from the chemistry of Polyethylene Terephthalate (PET). The polymer chain incorporates a rigid benzene ring, providing high strength and dimensional stability, while the ester bonds contribute to chemical resistance. Crucially, PET is hydrophobic, with a moisture regain of less than 0.4%. This means a polyester webbing strap maintains over 95% of its tensile strength in wet conditions, unlike nylon which can lose up to 15-20%. Its inherent resistance to UV degradation and hydrolysis makes it the default choice for demanding outdoor and long-term applications.

1.2 Engineering Comparison: Polyester, Nylon, and Polypropylene

Material selection is a function of the application's primary stress profile. A direct polyester vs nylon webbing strength and elongation comparison reveals complementary profiles. While nylon exhibits higher toughness and excellent abrasion resistance due to hydrogen bonding between amide groups, it suffers from moisture absorption and higher elongation. Polypropylene offers chemical inertness and low cost but has poorer UV resistance and a lower melting point.

The following table provides a data-driven comparison for engineering decision-making:

| Performance Parameter | Polyester (PET) | Nylon (PA6/PA66) | Polypropylene (PP) |

| Tensile Strength (Typical) | Very High (8-10 g/denier) | High (7-9 g/denier), reduces when wet | Moderate (4-6 g/denier) |

| Elongation at Break | Low (10-15%) - Excellent dimensional stability | High (15-30%) - Good energy absorption | Very High (20-35%) - Prone to creep |

| Moisture Absorption | ~0.4% - Negligible effect on properties | ~4.0% (PA6) - Lowers strength, increases elongation | ~0.01% - Hydrophobic |

| UV & Hydrolysis Resistance | Excellent - Inherently good, enhanced with stabilizers | Poor - Requires heavy stabilization | Poor - Requires heavy stabilization |

| Optimal Application Focus | Static or long-term load-bearing, outdoor use, where stability is key. | Dynamic loading, high abrasion environments, where flexibility and toughness are critical. | Chemical environments, lightweight, low-cost applications where high elongation is acceptable. |

Part 2: Decoding Specifications – The Language of Professional Procurement

2.1 Key Performance Indicators (KPIs) and Test Methods

Beyond the generic "weight capacity," professional procurement relies on standardized KPIs. These include breaking strength (ASTM D5034/D6775), elongation at specified load, tear strength (ASTM D5587), and abrasion resistance (Martindale or Taber tests). For UV resistant polyester webbing for outdoor furniture, colorfastness to light (AATCC 16) and accelerated weathering (Xenon Arc per ISO 4892-2) are non-negotiable test reports to request.

Understanding standard hierarchies is crucial. Commercial standards (e.g., ASTM, EN) define baseline safety. In contrast, a high-tenacity polyester webbing specification military standard, such as those outlined in MIL-W-xxxxx series or SAE AS specifications, imposes far stricter requirements. These typically involve:

- Batch-level testing for every production lot.

- Extended testing over extreme temperature ranges (-54°C to +85°C).

- Specific resistance to fuels, oils, and fungal growth.

- Full traceability of raw materials and manufacturing processes.

Specifications like these ensure reliability in the most critical applications and are a hallmark of advanced manufacturing capability.

2.3 The Customization Spectrum: Colors, Prints, and Functional Treatments

Meeting brand identity or functional needs often requires customization. A custom color printed polyester webbing strap can be achieved via:

- Solution/Dope Dyeing: Pigment is added to the polymer melt before extrusion. This offers supreme UV and wash fastness, ideal for UV resistant polyester webbing for outdoor furniture.

- Yarn Dyeing: Yarns are dyed before weaving, excellent for heather effects or specific color matches.

- Post-Weave Printing: Techniques like thermal transfer or screen printing apply design to the surface. Durability varies by ink and process.

The choice impacts cost, lead time, and durability, and should be discussed with a technical supplier early in the design process.

Part 3: Application Engineering – Matching Webbing to Critical Use Cases

3.1 Outdoor Durability: Engineering for Solar and Environmental Resistance

For UV resistant polyester webbing for outdoor furniture, automotive, or marine applications, material selection is just the start. Engineering involves the use of UV stabilizers (HALS - Hindered Amine Light Stabilizers) and antioxidants masterbatched into the PET resin. According to the latest research compiled by the European Chemicals Agency (ECHA), next-generation polymeric HALS are showing improved compatibility and longer-term effectiveness in protecting polymers from photo-oxidative degradation, a key factor in extending service life for outdoor textiles.

Performance must be validated via accelerated weathering tests, where samples are exposed to cycles of intense UV light, heat, and moisture to simulate years of outdoor exposure in weeks.

3.2 Lifting, Rigging, and Load Securement: A Calculus of Safety

Specifying heavy-duty polyester webbing straps for lifting and rigging is governed by safety engineering, not just strength. The fundamental equation involves the Minimum Breaking Strength (MBS), the Design Factor (often 5:1 or 7:1 for lifting), and the resultant Working Load Limit (WLL). For instance, a strap with an MBS of 10,000 lbs and a 5:1 design factor has a WLL of 2,000 lbs. These straps must comply with stringent regulations (e.g., OSHA 1926.251, ASME B30.9) and are often required to have permanent, legible labeling stating their WLL. Reputable manufacturers perform proof testing on a statistical sample from every batch.

3.3 Other High-Stakes Applications

Polyester webbing's stability and strength make it suitable for automotive seat belts (governed by FMVSS 209), lightweight cargo netting, and tactical gear. In each case, the relevant industry-specific standard dictates the exact performance and testing protocol.

Part 4: Strategic Sourcing – Partnering with a Professional Manufacturer

A manufacturer's capability directly impacts product reliability. Key evaluation criteria include:

- Vertical Integration & Control: Control over the process from polymer chip or filament yarn to finished webbing ensures consistency.

- In-House Laboratory: The ability to conduct standard tensile, colorfastness, and abrasion tests is a minimum. Advanced labs offer accelerated weathering and chemical resistance testing.

- Quality Management System: ISO 9001 certification provides a framework for consistent process control and continuous improvement.

- Technical Collaboration: The supplier should act as an engineering partner, capable of advising on weave construction, finish, and customization for optimal performance.

Established manufacturers, such as those with decades of experience in textile engineering like Fengrun Rope Weaving Co., Ltd., typically embody these principles. Their focus on strict quality control, a dedicated technical team, and a comprehensive material portfolio (polyester, nylon, polypropylene) allows them to guide clients beyond price to a value-based specification that ensures long-term performance and compliance.

4.1 The Procurement Workflow: From RFQ to Reliable Delivery

A professional procurement process should include: 1) Submitting a detailed Technical Data Sheet with all required KPIs; 2) Evaluating provided samples with independent or witnessed testing; 3) Reviewing and approving pre-production samples for custom color printed polyester webbing strap orders; 4) Requiring and reviewing Certified Test Reports for the production batch; and 5) Conducting periodic supplier audits.

Conclusion: Building Product Integrity from the Component Up

Selecting a polyester webbing strap is a foundational engineering decision. By understanding the material science, demanding validated performance data, and partnering with a manufacturer whose capabilities align with the application's criticality, B2B buyers mitigate risk and build inherent reliability into their products. In an era where product liability and sustainability are paramount, this technical, specification-driven approach is not just best practice—it is essential for long-term competitiveness.

Frequently Asked Questions (FAQs)

1. For a safety-critical lifting application, what documentation is mandatory from the webbing manufacturer?

For heavy-duty polyester webbing straps for lifting and rigging, you must obtain a Certificate of Conformity (CoC) and a Test Report from an accredited laboratory for the specific production batch. The test report should verify the Minimum Breaking Strength (MBS) and confirm compliance with the relevant standard (e.g., EN 1492-1). The straps themselves must be permanently marked with the Working Load Limit (WLL), manufacturer identification, and manufacturing standard.

2. How can I verify claims of "UV resistance" for outdoor furniture webbing?

Do not rely on marketing terms alone. Request a quantitative test report, typically for UV resistant polyester webbing for outdoor furniture. Look for data from an accelerated weathering test (e.g., ISO 4892-2 using a Xenon Arc lamp). The report should show the retained tensile strength and color change (Delta E) after a specified number of kilojoule exposures (e.g., 600 kJ/m²). A professional manufacturer will have this data for their stabilized webbing products.

3. What is the practical difference between a standard and a "high-tenacity" polyester webbing?

High-tenacity (HT) polyester yarn is spun with a higher degree of polymer orientation, resulting in a higher tensile strength per unit weight (denier). In practice, this means a high-tenacity polyester webbing specification military standard or a heavy-duty industrial strap can be made lighter and thinner for the same breaking strength, or stronger at the same thickness. It is a premium material used where maximizing strength-to-weight ratio or achieving extreme strength in a limited space is critical.

4. What are the key factors affecting the cost of a custom printed webbing strap?

The cost of a custom color printed polyester webbing strap is driven by: Order Quantity (setup costs are amortized over the meterage), Number of Colors (each color adds a printing station/setup), Printing Method (solution dyeing is cost-effective for large runs, transfer printing for short runs with complex graphics), and Webbing Base Material (specifications like width, thickness, and special treatments). Providing a detailed specification sheet to multiple qualified suppliers is the best way to obtain comparable quotes.

5. Why is polyester often recommended over nylon for long-term static tie-down applications?

This recommendation stems from the fundamental polyester vs nylon webbing strength and elongation comparison. Nylon exhibits higher "creep" or permanent elongation under sustained load, especially in humid conditions. Polyester has very low creep due to its low moisture absorption and higher initial modulus. Therefore, for applications like securing cargo on a truck for a multi-day journey or permanent architectural tie-downs, a polyester webbing strap will maintain tension and security more reliably over time.

English

English  中文简体

中文简体