We are a national high-tech enterprise. At present, there are many kinds of self-woven and cooperatively processed fabrics, including microfiber warp-knitted towel cloth, weft-knitted towel cloth, coral fleece, etc.

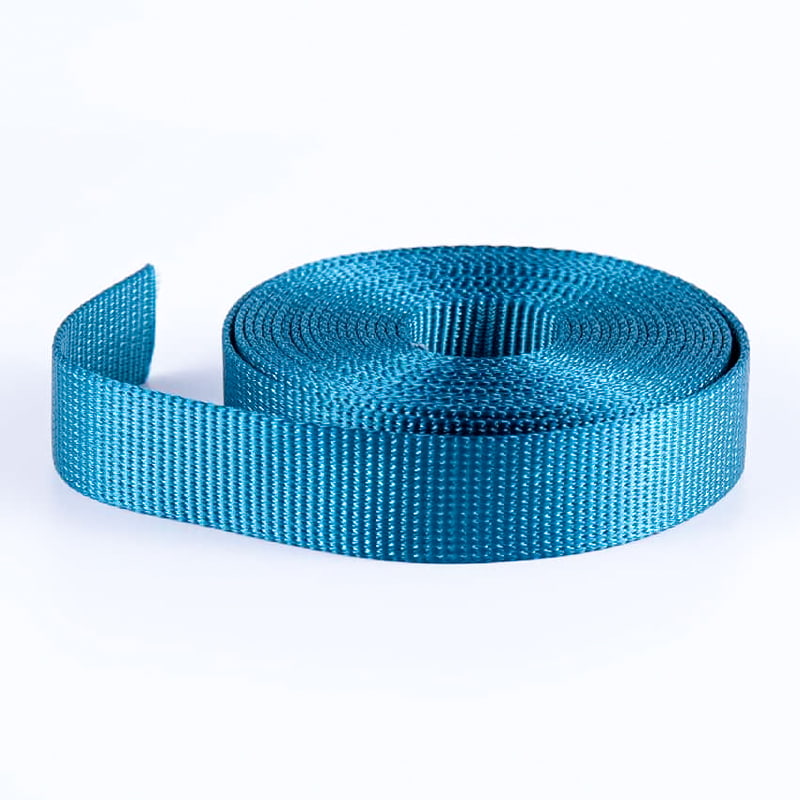

The global textile industry is undergoing a paradigm shift towards circularity, placing Eco-friendly Nylon Webbing Straps at the forefront of sustainable procurement. Fengrun Rope Weaving Co., Ltd., established in 2000 in Haining, Zhejiang, has evolved alongside this movement. With over two decades of manufacturing excellence, our technical team operates modern machinery to deliver high-performance solutions in ropes, webbing, and braided belts. As a comprehensive manufacturer, we integrate strict quality control with innovative material science to serve global markets, including the United States, Russia, India, and Europe.

- 1 1. Material Engineering: Mechanical Integrity of Recycled Polymers

- 2 2. Specialized Applications for High-Performance Sectors

- 3 3. Sustainable Manufacturing and Certification Standards

- 4 4. Manufacturing Excellence at Fengrun Weaving

- 5 5. Conclusion: A Commitment to Durable Innovation

- 6 Frequently Asked Questions (FAQ)

1. Material Engineering: Mechanical Integrity of Recycled Polymers

In the evaluation of sustainable fasteners, engineers often scrutinize the performance parity between recycled and virgin materials. A common concern is whether high-tensile eco-friendly nylon webbing straps vs. virgin nylon can provide equivalent load-bearing safety factors. Technical analysis reveals that through advanced purification and repolymerization, recycled Nylon 6 and 6,6 can achieve nearly identical molecular weight distributions. This ensures that the resulting webbing maintains the high tenacity required for industrial safety standards while reducing the carbon footprint associated with petroleum-based extraction.

| Technical Parameter | Virgin Nylon 6,6 Webbing | High-tensile eco-friendly nylon webbing straps |

| Tensile Strength (cN/dtex) | 8.0 - 9.5 | 7.8 - 9.2 |

| Elongation at Break (%) | 15 - 25% | 18 - 28% |

| Melting Point (Celsius) | 255 - 260 | 250 - 258 |

| Environmental Impact (LCA) | High Fossil Fuel Usage | Up to 70% CO2 Reduction |

2. Specialized Applications for High-Performance Sectors

The versatility of nylon webbing allows it to penetrate diverse industrial sectors, provided the material is engineered for specific environmental stressors. For the outdoor industry, providing recycled nylon webbing straps for sustainable outdoor gear requires a focus on abrasion resistance and low moisture absorption. At Fengrun, our belts and ropes are engineered to withstand the rigorous demands of export-grade goods, ensuring durability in bags, garments, and tactical gear.

Environmental Resilience in Pet and Safety Products

In the pet accessories market, longevity is often limited by photo-degradation. Utilizing UV resistant eco-friendly nylon webbing straps for pet products is essential for maintaining the structural integrity of collars and leashes exposed to direct sunlight. Our manufacturing process incorporates UV-stabilizing additives at the molecular level, preventing the "chalking" and brittle failure common in lower-grade recycled plastics.

3. Sustainable Manufacturing and Certification Standards

For B2B wholesalers, the legitimacy of "eco-friendly" claims must be backed by verifiable data. Sourcing eco-friendly nylon webbing straps with GRS certification wholesale ensures a transparent chain of custody from the waste source to the finished strap. According to the latest report by the Textile Exchange, the preferred fiber market share is expanding rapidly, with recycled synthetics now being a mandatory requirement for major international brands seeking to comply with emerging ESG (Environmental, Social, and Governance) disclosure regulations.

Source: Textile Exchange Preferred Fiber & Materials Market Report

Innovative Dyeing Techniques for Resource Conservation

Standard aqueous dyeing is water-intensive; therefore, we implement dope dyed eco-friendly nylon webbing straps for water saving. Dope dyeing, also known as solution dyeing, involves adding color pigments to the polymer melt before extrusion. This process eliminates the need for high-pressure dyeing baths, significantly reducing chemical runoff and energy consumption.

According to the latest technical standards from the International Organization for Standardization (ISO) regarding environmental management, water-efficient dyeing processes like dope dyeing can reduce liquid waste discharge by over 80% compared to traditional piece-dyeing methods.

Source: ISO 14046:2014 Environmental management — Water footprint

4. Manufacturing Excellence at Fengrun Weaving

Our facility in Haining is equipped with high-speed needle looms and computerized braiding machines, allowing us to maintain the principle of "Quality and Innovation in Equal Measure." We offer a wide range of specifications in polypropylene, polyester, cotton, and nylon. Our core capabilities include:

- Custom Sample Development: We welcome custom orders based on provided samples to meet precise client specifications.

- Quality Control Systems: Strict monitoring of weaving tension and color fastness.

- Global Logistics: Proven track record of on-time delivery for the United States, Russia, India, and Europe.

5. Conclusion: A Commitment to Durable Innovation

The choice to integrate Eco-friendly Nylon Webbing Straps into your product line is a strategic investment in both quality and the planet. Fengrun Rope Weaving Co., Ltd. remains dedicated to providing durable, wear-resistant, and aesthetically diverse webbing solutions. By combining 25 years of technical expertise with the latest in green textile technology, we ensure our partners receive competitive pricing without compromising on industrial performance.

Frequently Asked Questions (FAQ)

- Q1: Are eco-friendly nylon straps as strong as traditional ones?

A: Yes, through advanced GRS-certified recycling processes, the tensile strength of our eco-friendly straps is engineered to be within 5% of virgin nylon, meeting most industrial safety requirements. - Q2: What is the benefit of Dope Dyeing for my brand?

A: Dope dyeing provides superior color fastness to light and washing while allowing your brand to claim significant water and energy savings in your sustainability reports. - Q3: Can you produce custom widths and colors for eco-friendly webbing?

A: Absolutely. We offer a wide color range and can customize specifications based on your samples or technical drawings. - Q4: How does UV resistance affect the lifespan of the webbing?

A: UV resistance prevents the polymer chains from breaking down under sunlight, extending the functional life of outdoor gear and pet products by up to 3 times in high-exposure environments. - Q5: Do your products comply with European REACH standards?

A: Yes, as a professional manufacturer focused on export goods, all our materials undergo strict quality control to ensure compliance with international chemical safety regulations.

English

English  中文简体

中文简体