We are a national high-tech enterprise. At present, there are many kinds of self-woven and cooperatively processed fabrics, including microfiber warp-knitted towel cloth, weft-knitted towel cloth, coral fleece, etc.

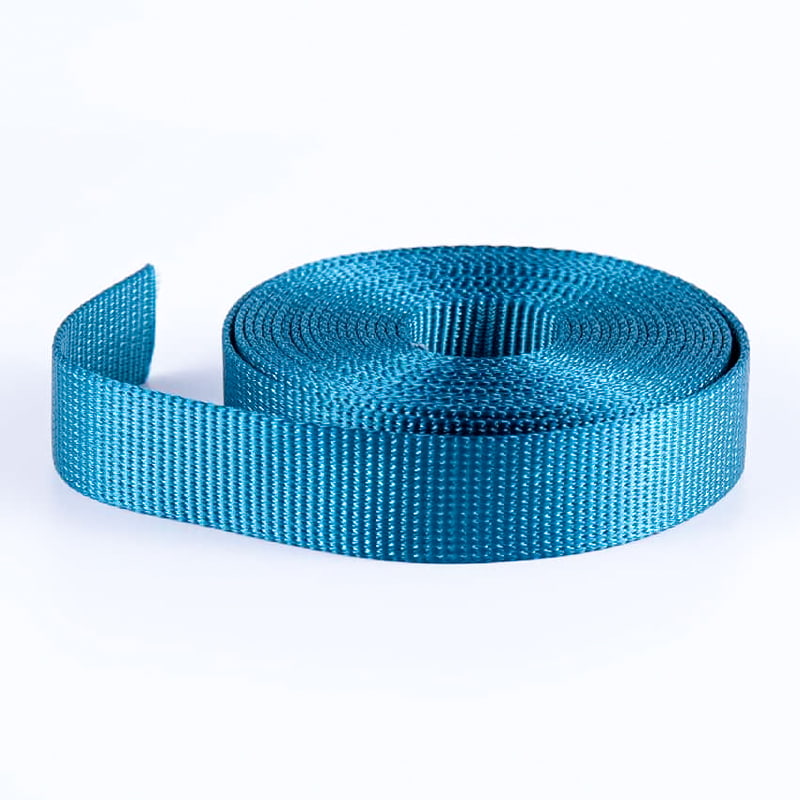

In the world of industrial fastening and securing solutions, Polyester Webbing Straps have established themselves as one of the most versatile and reliable materials across countless applications. These durable straps, woven from polyester yarns, offer an exceptional balance of strength, durability, and resistance to environmental factors that make them suitable for everything from lightweight packaging to heavy-duty cargo securing. As industries continue to demand higher performance from their materials while maintaining cost-effectiveness, polyester webbing has emerged as the go-to solution for applications where reliability cannot be compromised.

The Engineering Excellence Behind Polyester Webbing

The remarkable performance characteristics of Polyester Webbing Straps stem from the intrinsic properties of polyester fibers combined with advanced weaving technologies. Polyester polymer chains feature strong molecular bonds that provide exceptional tensile strength, allowing the webbing to withstand substantial loads without stretching or breaking. The manufacturing process begins with the extrusion of polyester chips into continuous filaments, which are then spun into yarns of varying thicknesses depending on the required strength specifications. These yarns undergo precision weaving on industrial looms that create tight, consistent patterns ensuring uniform distribution of stress across the entire width of the webbing. The result is a material that maintains dimensional stability under load, resists UV degradation from sun exposure, and demonstrates minimal water absorption compared to natural fiber alternatives. This combination of properties makes polyester webbing particularly valuable in applications where consistent performance under variable conditions is essential for safety and reliability.

Material Properties and Performance Characteristics

The exceptional suitability of Polyester Webbing Straps for demanding applications arises from a unique combination of material properties that outperform many alternatives. Polyester exhibits less than 3% elongation at working loads, providing minimal stretch and excellent load control – a critical characteristic for cargo securing and lifting applications. The material maintains its strength properties across a wide temperature range from -40°C to 120°C, performing reliably in both freezing cold and hot environments. Unlike nylon, polyester absorbs less than 1% moisture, meaning its strength remains consistent in wet conditions without the need for derating. The inherent resistance to UV radiation, mold, mildew, and most chemicals ensures long service life even in harsh outdoor or industrial environments. These technical characteristics combine to create a webbing material that delivers predictable, reliable performance across diverse applications and environmental conditions.

- Minimal stretch (3-5%) under load for superior load control

- High resistance to UV degradation and environmental factors

- Low moisture absorption (0.4%) maintaining strength when wet

- Excellent abrasion resistance for extended service life

- Inherent resistance to mold, mildew, and most chemicals

Weaving Techniques and Construction Varieties

The manufacturing of Polyester Webbing Straps utilizes specialized weaving techniques that optimize the material for specific applications and performance requirements. Plain weave constructions create a simple over-and-under pattern that provides balanced strength characteristics and good flexibility, making them suitable for general-purpose applications. Twill weaves feature a diagonal rib pattern that offers enhanced durability and a softer hand, often used for apparel and equipment straps. Herringbone patterns provide maximum stability and resistance to twisting, ideal for technical and safety applications where precise handling is critical. Tubular weaves create a hollow construction that offers cushioning properties for shoulder straps and harnesses. The density of the weave directly impacts the webbing's performance, with tighter weaves providing higher strength and better resistance to abrasion, while looser weaves offer increased flexibility and reduced weight. This variety of construction methods enables manufacturers to produce webbing optimized for everything from delicate electronic equipment to multi-ton industrial loads.

- Plain weave for general purpose applications with balanced performance

- Twill weave for enhanced durability and flexibility

- Herringbone pattern for maximum stability and twist resistance

- Tubular construction for cushioning and comfort applications

- Reinforced edges for high-wear applications and heavy loads

Applications Across Industries: Versatility and Reliability

The application spectrum for Polyester Webbing Straps spans virtually every industry where secure fastening, lifting, or restraint is required. In transportation and logistics, these straps secure cargo of all types, from consumer goods on pallets to heavy machinery on flatbed trucks, with their minimal stretch ensuring loads remain tight during transit. The automotive industry utilizes polyester webbing for seatbelts, cargo nets, and tie-down systems where safety and reliability are paramount. In outdoor and sporting goods, the material appears in backpack straps, tent guylines, and climbing gear where strength-to-weight ratio and environmental resistance are critical. The furniture industry incorporates polyester webbing in seating suspensions, while the medical field uses it for patient restraints and mobility aids. This remarkable versatility stems from polyester's ability to be engineered to specific requirements through variations in weave pattern, thickness, width, and finish treatments, creating tailored solutions for diverse operational needs.

Transportation and Cargo Securing Solutions

In transportation applications, Polyester Webbing Straps provide critical securing solutions that ensure safety and load integrity during transit. Their minimal elongation characteristic is particularly valuable in this context, as it prevents load shift that can occur when straps stretch during vehicle movement and vibration. For trucking and logistics, these straps are available in widths from 1 inch to 4 inches with working load limits ranging from 1,100 to 5,400 pounds, allowing appropriate selection based on cargo weight and securing requirements. The UV resistance ensures that straps used in open transport maintain their strength despite prolonged sun exposure, while the low moisture absorption prevents strength reduction in rainy conditions. Color coding options facilitate easy identification of different strap capacities or ownership, improving inventory management and safety compliance. These characteristics make polyester the preferred choice for professional cargo securing where load stability and predictable performance cannot be compromised.

- Ratchet straps for heavy-duty cargo securing with precise tension control

- Cam buckle straps for medium-duty applications with quick operation

- Wheel nets and motorcycle tie-downs for vehicle transport

- Container lashing systems for international shipping

Safety and Fall Protection Systems

The use of Polyester Webbing Straps in safety and fall protection systems demonstrates the material's reliability in life-critical applications. In personal fall arrest systems, polyester webbing forms the core component of full-body harnesses, lanyards, and self-retracting lifelines where failure is not an option. The material's predictable elongation characteristics help reduce arrest forces in fall scenarios, while its abrasion resistance ensures long service life in demanding work environments. For industrial safety applications, polyester webbing appears in guardrails, safety barriers, and load containment systems where strength and durability are essential. The compatibility with various hardware components – including D-rings, snap hooks, and buckles – allows for the creation of comprehensive safety systems tailored to specific workplace hazards. Rigorous testing and certification processes ensure that safety-rated polyester webbing consistently meets or exceeds international standards for performance in these critical applications.

- Full-body harnesses for fall arrest in construction and industry

- Safety lanyards and self-retracting lifelines

- Industrial guardrails and perimeter protection systems

- Load restraint assemblies for material handling safety

Technical Specifications and Performance Standards

The performance of Polyester Webbing Straps is governed by rigorous technical specifications and international standards that ensure consistency and reliability across applications. Tensile strength ratings typically range from 4,000 pounds for 1-inch webbing to over 16,000 pounds for 3-inch versions, with working load limits generally set at one-fifth of the ultimate strength for safety margins. Abrasion resistance is quantified through standardized tests that measure the number of cycles until failure when rubbed against standardized surfaces under controlled pressure. UV resistance is evaluated through accelerated weathering tests that simulate years of sun exposure, with high-quality polyester webbing typically retaining over 80% of its original strength after 1,000 hours of exposure. These technical parameters are verified through independent testing laboratories and compliance with standards such as AS/NZS 4380 for safety harnesses, EN 12195-2 for load restraint assemblies, and UL 985 for fire resistance where applicable.

Comparison with Alternative Webbing Materials

Understanding the advantages of Polyester Webbing Straps requires comparison with other common webbing materials to highlight its unique position in the materials spectrum. Compared to nylon webbing, polyester offers significantly lower stretch (3-5% versus 15-20% for nylon), making it superior for applications where load stability is critical. While nylon's stretch can be advantageous for dynamic loading situations, polyester's stability provides better control for static loads. Against polypropylene, polyester demonstrates superior UV resistance and strength, though polypropylene floats and offers better chemical resistance to certain acids and bases. Compared to natural fibers like cotton, polyester provides consistently higher strength, complete resistance to rot and mildew, and minimal water absorption. This balance of properties positions polyester as the ideal choice for applications requiring predictable performance, environmental resistance, and long-term durability without the maintenance requirements of natural fibers or the stretch characteristics of nylon.

When selecting webbing materials for specific applications, consider these comparative characteristics:

| Performance Characteristic | Polyester Webbing | Nylon Webbing | Polypropylene Webbing |

| Elongation at Working Load | 3-5% | 15-20% | 15-25% |

| Moisture Absorption | 0.4% | 4-5% | 0% |

| UV Resistance | Excellent | Good | Poor to Fair |

| Abrasion Resistance | Excellent | Excellent | Fair to Good |

| Strength Retention When Wet | 100% | 80-90% | 100% |

FAQ

What is the difference between polyester and nylon webbing?

The primary difference between Polyester Webbing Straps and nylon alternatives lies in their elongation characteristics and moisture absorption. Polyester exhibits minimal stretch (3-5% at working load) compared to nylon's significant elongation (15-20%), making polyester preferable for applications where load stability is critical, such as cargo securing and lifting operations. Additionally, polyester absorbs only 0.4% moisture versus nylon's 4-5% absorption, meaning polyester maintains its full strength when wet while nylon loses 10-20% of its strength in wet conditions. Nylon's greater stretch can be advantageous for applications requiring shock absorption, such as climbing fall protection, but for most industrial and securing applications, polyester's stability and consistent performance make it the preferred choice.

How long do polyester webbing straps last?

The service life of Polyester Webbing Straps varies significantly based on usage conditions, maintenance practices, and exposure to degrading elements. With proper care and storage, polyester webbing used in moderate conditions typically lasts 3-5 years, while heavy industrial use may reduce this to 1-3 years. UV exposure is the primary factor in degradation, with straps used outdoors requiring more frequent replacement than indoor applications. Regular inspection for signs of wear – including fading, abrasion, cuts, or chemical damage – is essential for determining when replacement is necessary. Most manufacturers recommend retiring safety-critical webbing after 5 years regardless of visible condition due to potential UV degradation that may not be visibly apparent. Proper storage away from direct sunlight, chemicals, and moisture when not in use can significantly extend the functional life of polyester webbing.

Can polyester webbing be used for lifting applications?

Yes, Polyester Webbing Straps are widely used in lifting applications, particularly where protection of delicate surfaces is important. Polyester slings offer excellent strength characteristics with working load limits ranging from 1,000 to 300,000 pounds depending on the configuration, width, and number of piles. The material's flexibility allows it to conform to irregular shapes without damaging delicate surfaces, while its minimal stretch provides precise load control. For overhead lifting, polyester slings must be certified and marked in accordance with ASME B30.9 standards, with regular inspection required to ensure ongoing safety. Color-coded identification systems typically indicate capacity ranges for quick visual reference. While polyester offers excellent general-purpose lifting capabilities, specialized applications may require alternative materials – for high-temperature environments above 100°C, for example, or when exceptional abrasion resistance is the primary concern.

How should I clean and maintain polyester webbing?

Proper maintenance of Polyester Webbing Straps involves regular cleaning and inspection to ensure ongoing performance and safety. For routine cleaning, mild soap and lukewarm water with gentle scrubbing effectively removes most dirt and contaminants. Avoid harsh chemicals, bleach, or solvents that can degrade the polyester fibers or affect dye stability. After cleaning, rinse thoroughly and air dry away from direct heat sources before storage. Regular inspection should check for signs of UV degradation (fading or stiffness), abrasion (fuzzing or thinning), cuts or tears, chemical damage (discoloration or hardening), and worn stitching. Storage should occur in cool, dry conditions away from direct sunlight, chemicals, and moisture. Proper maintenance not only extends service life but, more importantly, ensures the webbing remains safe for its intended applications.

What safety standards apply to polyester webbing?

Polyester Webbing Straps used in safety-critical applications must comply with various international standards depending on their specific use. For fall protection equipment, EN 361 and ANSI Z359.1 govern harness construction, while EN 354 and ANSI Z359.13 cover lanyards. Load restraint systems for transportation must meet EN 12195-2 for webbing assemblies and ISO 27956 for cargo securing in road vehicles. Lifting slings conform to ASME B30.9 and EN 1492-1 standards, which specify design factors, marking requirements, and inspection protocols. Fire resistance standards like UL 985 may apply to webbing used in certain environments. These standards ensure consistent performance, establish safety factors, and provide testing methodologies to verify that webbing meets minimum requirements for its intended applications. Compliance with relevant standards is typically indicated by certification marks from accredited testing laboratories.

English

English  中文简体

中文简体