We are a national high-tech enterprise. At present, there are many kinds of self-woven and cooperatively processed fabrics, including microfiber warp-knitted towel cloth, weft-knitted towel cloth, coral fleece, etc.

- 1 Unveiling the Craft: What Makes Jacquard Webbing Unique?

- 2 Material Matters: Choosing the Right Base for Your Project

- 3 From Concept to Creation: The Power of Customization

- 4 Industry Spotlights: Where Decorative Straps Transform Products

- 5 Sourcing with Confidence: Partnering with the Right Manufacturer

- 6 FAQ

Unveiling the Craft: What Makes Jacquard Webbing Unique?

Decorative jacquard webbing straps are far more than simple functional bands; they are intricately engineered textiles where durability meets high-resolution artistry. Unlike standard woven webbing, which typically features simple, repetitive patterns like stripes or checks, jacquard webbing is defined by its complex, often pictorial or highly detailed designs woven directly into the fabric structure. This capability stems from the historic Jacquard loom mechanism, now powered by advanced computerized systems, which allows for individual control over hundreds of warp threads. This precise control enables the creation of sharp contrasts, elaborate logos, photographic-like images, and sophisticated patterns with multiple colors, all woven seamlessly into a single, strong strap.

The uniqueness of jacquard webbing lies in its integrated construction. The design is not printed on the surface but is an inherent part of the webbing itself.

- Unmatched Durability: Because the pattern is woven in, it cannot peel, crack, or fade away like surface prints, making it ideal for high-wear applications.

- Texture and Dimension: The weaving process creates a subtle, tactile texture that adds to the premium feel and visual depth of the design.

- Design Fidelity: It allows for the reproduction of highly detailed brand logos, typography, and complex graphic elements with remarkable clarity.

- Structural Integrity: Despite the complex patterning, modern manufacturing ensures the webbing retains high tensile strength for load-bearing uses.

Material Matters: Choosing the Right Base for Your Project

The performance, aesthetics, and feel of a decorative jacquard webbing strap are fundamentally determined by its base material. Selecting the appropriate fiber is a critical decision that balances functional requirements with design intent. For manufacturers like Fengrun Rope Weaving Co., Ltd., which works with polypropylene, polyester, cotton, and nylon, the choice of material directly influences the strap's application suitability, from soft luggage handles to rugged outdoor gear straps. Understanding the inherent properties of each material allows designers and product developers to make informed choices that enhance the end product's user experience and longevity.

Natural Feel: The Appeal of Cotton Jacquard Webbing for Bag Handles

There is a growing demand for natural, sustainable, and comfortable materials in fashion and accessories, making cotton jacquard webbing for bag handles a premium choice. Cotton offers a soft, breathable, and skin-friendly texture that synthetic materials often struggle to replicate, providing exceptional comfort for handheld or shoulder-carry items. Its natural matte finish lends an organic, high-quality aesthetic that appeals to brands emphasizing craftsmanship and eco-consciousness. For tote bags, duffels, and specialty handbags, cotton jacquard straps add a touch of understated luxury. While historically perceived as less strong than synthetics, modern, densely woven cotton jacquard from specialized producers offers substantial strength for everyday bag use, coupled with excellent print clarity for woven logos.

Synthetic Solutions: Polyester, Nylon, and Polypropylene Options

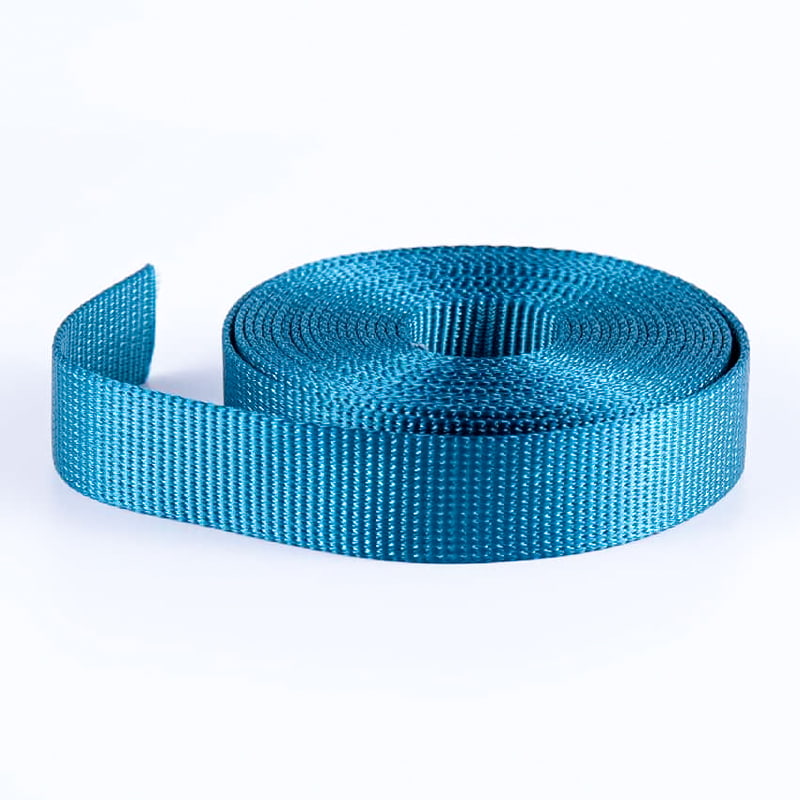

Synthetic fibers provide a suite of performance-oriented properties crucial for demanding applications. Polyester is the workhorse, prized for its excellent colorfastness (resistance to UV fading), low moisture absorption, and high strength-to-weight ratio, making it perfect for outdoor furniture straps, pet products, and promotional items. Nylon offers superior elasticity, abrasion resistance, and toughness, ideal for tactical gear, backpacks, and adjustable straps. Polypropylene is lightweight, hydrophobic (floats on water), and cost-effective, commonly used in casual tote bags and industrial applications. The choice depends on the specific balance of strength, weather resistance, color permanence, and budget required.

| Material | Key Advantages | Ideal Applications |

| Cotton | Soft hand feel, breathable, natural aesthetic, biodegradable. | Premium bag handles, fashion accessories, home decor accents, apparel. |

| Polyester | High strength, excellent UV/colorfastness, mildew resistant, durable. | Outdoor furniture, automotive interiors, luggage, long-life promotional straps. |

| Nylon | Exceptional abrasion resistance, elasticity, and toughness. | Backpacks, sports equipment, tactical gear, heavy-duty adjustable straps. |

| Polypropylene | Lightweight, moisture-resistant, cost-effective. | Lightweight totes, non-critical straps, industrial bundling. |

From Concept to Creation: The Power of Customization

The true potential of decorative jacquard webbing is unlocked through customization. Off-the-shelf patterns serve a purpose, but custom decorative jacquard webbing straps become a proprietary brand asset, offering an unparalleled tool for product differentiation and storytelling. For brands across fashion, furniture, and consumer goods, a custom-woven strap featuring a unique pattern, integrated logo, or signature colorway transforms a functional component into a recognizable trademark. This process demands a collaborative partnership with a manufacturer possessing both technical prowess and creative problem-solving skills, capable of translating a two-dimensional design into a durable, woven reality that aligns with precise brand standards.

Industry Spotlights: Where Decorative Straps Transform Products

The application of decorative jacquard webbing straps is limited only by imagination, but several industries have mastered its use to add significant value.

Elevating Home Furnishings: Decorative Furniture Jacquard Webbing

In the home furnishings sector, decorative furniture jacquard webbing is a key detail that elevates design. It is extensively used as supportive and decorative strapping on the sides and backs of chairs, sofas, and ottomans, often in contrasting colors or patterns to create visual interest. It serves as functional yet attractive cording on cushion covers and as elegant tie-backs for curtains and drapes. The durability of jacquard weaving ensures these decorative elements withstand daily use without degrading, while the design integration allows furniture makers to create cohesive collections with a signature woven motif. This application perfectly aligns with manufacturers supplying the global furniture market, requiring webbing that meets both aesthetic and stringent durability standards.

Essentials for Fashion & Luggage: Woven Label Jacquard Straps Wholesale

For the fashion and luggage industries, branding is paramount. Sourcing woven label jacquard straps wholesale is a strategic decision for brands looking to scale production. These straps often function as both a carrying handle and a primary brand label, woven with the company logo and name. The wholesale model provides cost-efficiency and consistency across thousands of units, which is critical for major bag and luggage lines. A reliable manufacturer for such orders must guarantee not only color and pattern consistency across large production runs but also ensure the webbing meets weight-bearing specifications for safety. This vertical demands a supplier with robust quality control systems and the capacity to deliver large orders on time for global export, a core competency of established producers.

Sourcing with Confidence: Partnering with the Right Manufacturer

Identifying a reliable colorful patterned jacquard webbing manufacturer is the most critical step in the sourcing journey. The right partner does more than produce webbing; they act as a technical consultant, ensuring the chosen material, weave density, and design are optimized for the intended application. Key differentiators include in-house design support to prepare files for weaving, a transparent sampling process to approve colors and patterns, and vertically integrated production that controls quality from yarn sourcing to finishing. Manufacturers with a long-standing reputation, like Fengrun Rope Weaving Co., Ltd. established in 2000, bring accumulated expertise in navigating the technical challenges of complex jacquard weaving, ensuring that vibrant colors remain fast and intricate patterns remain sharp, batch after batch.

FAQ

What is the typical lead time and MOQ for custom jacquard webbing?

Lead times and Minimum Order Quantities (MOQs) vary significantly based on the project's complexity and the manufacturer's setup. For a new custom decorative jacquard webbing strap design, expect a development phase of 2-4 weeks for sampling, which includes creating a loom file and producing physical strike-offs for approval. Full production lead time after sample approval can range from 4-8 weeks, depending on order size and factory schedule. MOQs are typically based on minimum yarn usage and loom setup time. They can range from a few hundred meters for simpler designs on common materials to several thousand meters for complex, multi-color patterns. Reputable manufacturers will work with clients to find a feasible MOQ, especially for promising new projects.

How do I prepare a design file for custom jacquard weaving?

Preparing a design correctly is crucial for a successful outcome. Most manufacturers require a vector-based file (e.g., AI, EPS, or high-resolution PDF). Key guidelines include:

- Simplify Designs: Overly detailed gradients or photographic images may not translate well to weaving. Clean lines, solid color areas, and reduced color counts yield the best results.

- Define Colors Clearly: Use Pantone (PMS) color codes to specify exact color matches. This provides a universal standard for dyeing the yarn.

- Consider Repeat: Indicate if the pattern is a non-repeating logo or a seamless, repeating pattern. The manufacturer's technical team will then create the precise loom configuration.

- Consult Early: Engaging the manufacturer's design team early in the process can help optimize the artwork for the weaving process, avoiding costly revisions later.

Are there eco-friendly or recycled material options for jacquard webbing?

Yes, sustainable options are a major trend and increasingly available. Environmentally conscious manufacturers now offer webbing made from:

- Recycled PET (rPET): Made from post-consumer plastic bottles, this polyester offers performance similar to virgin polyester but with a significantly lower environmental footprint.

- Organic Cotton: Grown without synthetic pesticides, offering a natural and sustainable choice for applications where cotton is suitable.

- Bio-based Polymers: Emerging materials derived from renewable resources like corn or sugarcane.

When sourcing, inquire about Global Recycled Standard (GRS) or Oeko-Tex certifications to verify the eco-friendly claims and ensure the materials are free from harmful substances. This aligns with the growing demand for sustainable components in global markets.

What are the trending patterns and color palettes in decorative webbing?

Current trends reflect broader design movements. For 2024, there is a strong move towards:

- Nature-Inspired & Organic Patterns: Florals, leaf motifs, and abstract organic shapes are prominent.

- Textured and Tonal Designs: Patterns that create visual texture through subtle tonal variations of a single color, offering a sophisticated, minimalist look.

- Earthy and Neutral Color Palettes: Terracotta, olive green, warm beige, and stone gray are highly popular, moving away from bright primaries.

- Retro and Geometric Revivals: Mid-century modern stripes, checks, and geometric patterns are seeing a resurgence, often in updated colorways.

For brands, incorporating these trends through decorative furniture jacquard webbing or bag straps can instantly modernize a product line and connect with contemporary consumer aesthetics.

English

English  中文简体

中文简体