We are a national high-tech enterprise. At present, there are many kinds of self-woven and cooperatively processed fabrics, including microfiber warp-knitted towel cloth, weft-knitted towel cloth, coral fleece, etc.

Custom Woven Ribbon Tape Manufacturers

About Us

Pay attention to our latest news and exhibitions

READ OUR BLOG

-

Feb 02, 2026

What Are Decorative Jacquard Webbing Straps?

Imagine elevating a simple tote bag with a beautifully patterned handle, adding a pop of branded color to a garment's trim, or creating a unique, comfortable collar for a beloved pet. This transformative power lies in decorative jacquard webbing straps. These are not just functional straps; they are...

READ MORE -

Jan 27, 2026

The Engineering Guide to Decorative Jacquard Webbing Straps: Technical Integration and Manufacturing Excellence

In high-performance textile engineering, Decorative Jacquard Webbing Straps represent a sophisticated integration of structural durability and intricate aesthetic design. Unlike printed webbing, where patterns are applied to the surface, Jacquard weaving incorporates designs directly into the fabric...

READ MORE -

Jan 22, 2026

The Engineering Guide to Eco-friendly Nylon Webbing Straps: Material Science and Industrial Applications

The global textile industry is undergoing a paradigm shift towards circularity, placing Eco-friendly Nylon Webbing Straps at the forefront of sustainable procurement. Fengrun Rope Weaving Co., Ltd., established in 2000 in Haining, Zhejiang, has evolved alongside this movement. With over two decades ...

READ MORE

PRODUCTS Industry Knowledge

How do material choices affect the durability of woven ribbon tape?

The durability of woven ribbon tape is a critical concern for manufacturers, designers, and end-users alike. Whether used in apparel, bags, toys, or upholstery, the performance of woven ribbon tape is influenced heavily by the materials from which it is made. Understanding the relationship between material choice and tape longevity is essential for businesses looking to provide high-quality, reliable products.

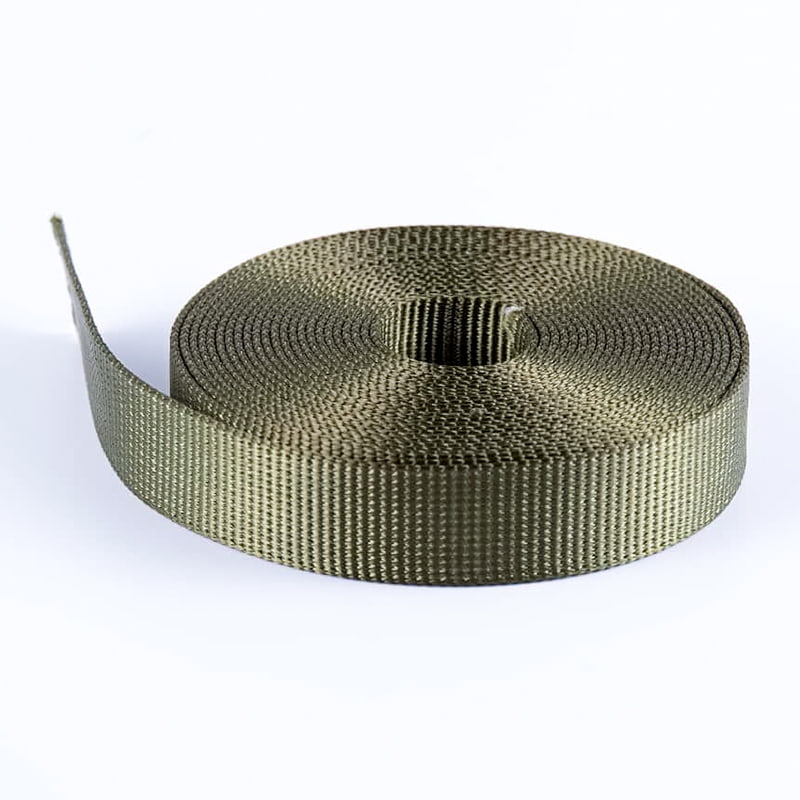

Understanding woven ribbon tape

Woven ribbon tape is a flat, narrow strip of fabric created through interlacing threads in a controlled pattern. Its applications range from functional uses, such as straps and belts, to decorative purposes in garments and accessories. Unlike printed or knitted tapes, woven tape’s structural integrity is inherently tied to the materials and weaving methods used during production.

The choice of fiber determines not only the tape’s tensile strength and flexibility but also its resistance to abrasion, environmental stressors, and long-term wear. Manufacturers such as Fengrun Rope Weaving Co., Ltd. produce tapes from a variety of fibers, including polypropylene, polyester, cotton, and nylon, offering customers both standard and customized solutions.

The role of materials in durability

Material composition directly affects the physical properties of woven ribbon tape. Different fibers offer unique characteristics, influencing strength, elasticity, abrasion resistance, and environmental tolerance. Choosing the right material depends on the intended use, budget, and durability requirements.

Polyester

Polyester is widely recognized for its strength, dimensional stability, and resistance to stretching or shrinking. Its synthetic nature provides excellent resistance to UV exposure, moisture, and chemicals.

For example, polyester woven ribbon tape maintains its structural integrity even under repeated tension, making it ideal for heavy-duty straps, bag handles, and industrial applications. In addition, polyester is compatible with colorful woven tape production, retaining bright hues even after frequent washing or prolonged sunlight exposure.

| Material | Key Properties | Durability Advantages |

|---|---|---|

| Polyester | High strength, abrasion-resistant, low stretch | Long-lasting under tension, retains color, resistant to environmental factors |

Nylon

Nylon is another synthetic fiber favored for its superior tensile strength and elasticity. Unlike polyester, nylon can absorb some shock or strain without permanent deformation, which is particularly valuable for tapes used in high-stress applications such as harnesses, luggage straps, or industrial bindings.

However, nylon can be more sensitive to UV light over time and may require special coatings or treatments to maintain its durability in outdoor environments. For woven ribbon tape intended for export products like bags or belts, nylon provides a balance of strength and flexibility, ensuring that the tape performs consistently under repetitive use.

Cotton

Cotton offers a natural, soft feel that is preferred in applications where comfort or aesthetics is critical, such as clothing trims or decorative woven ribbon tape. Cotton tapes are breathable, easy to dye, and provide a classic appearance.

While cotton excels in comfort and look, it generally has lower tensile strength and moisture resistance than synthetic fibers. Prolonged exposure to water, sunlight, or friction can accelerate wear. Therefore, cotton tapes are better suited for indoor decorative purposes rather than heavy-duty functional applications.

Polypropylene

Polypropylene is a lightweight, chemically resistant polymer with notable resistance to moisture and mildew. This makes polypropylene tapes suitable for outdoor gear, marine products, and eco-friendly woven ribbon tape solutions where durability under environmental stress is necessary.

Polypropylene is less heat-resistant than polyester or nylon, which should be considered when tapes may undergo ironing, high-temperature processing, or prolonged exposure to heat sources. The low density also makes polypropylene woven ribbon tape more cost-effective for large-scale applications without compromising basic performance.

Factors influencing tape longevity beyond material

While the choice of fiber is foundational, other aspects of production influence the durability of woven ribbon tape. These include weaving technique, thread density, finishing processes, and quality control standards.

Weaving technique

Different weaving methods, such as twill, satin, or plain weave, affect the tape’s strength, flexibility, and edge integrity. For instance, polyester twill tape provides enhanced durability and smooth edges, reducing fraying and extending lifespan.

Thread interlacing density also matters: higher thread density increases tensile strength and wear resistance but may slightly reduce flexibility. Manufacturers like Fengrun Rope Weaving Co., Ltd. optimize weaving patterns based on both material type and intended application.

Finishing and treatment

Finishing processes such as heat-setting, coating, or dye fixation can significantly enhance tape durability. Heat-setting stabilizes synthetic fibers, preventing unwanted stretching or deformation during use. Coatings can improve abrasion resistance and water repellence, while high-quality dye fixation ensures that colorful woven tape maintains vibrancy even under repeated washing or sunlight exposure.

Quality control

Consistent quality is essential to durability. Advanced inspection equipment and testing labs allow manufacturers to assess tensile strength, elongation, abrasion resistance, and colorfastness. High-quality woven ribbon tape undergoes stringent quality checks to ensure it performs reliably across its expected lifespan. This is especially important for export goods, industrial applications, and consumer products where failure could result in functional or reputational issues.

Sustainability and material choices

In addition to durability, material selection can impact the environmental footprint of woven ribbon tape. Companies increasingly prioritize eco-friendly nylon webbing or recycled polyester fibers to reduce environmental impact. These materials can achieve comparable durability to traditional fibers while contributing to sustainability goals.

For buyers seeking durable, sustainable woven ribbon tape, it is crucial to verify both the material origin and production processes, ensuring that recycled or low-carbon materials are used without compromising tape performance.

Industry applications and material requirements

The end-use of woven ribbon tape often dictates material choice. Understanding the specific requirements of various industries helps in selecting the most durable options.

Garments and fashion accessories

For clothing trims, belts, or decorative tapes, soft, aesthetically pleasing fibers like cotton or polyester are preferred. Here, durability is measured not only by tensile strength but also by resistance to fraying and color retention. Multi-colored or patterned woven ribbon tape is common, requiring materials that hold dyes effectively.

Bags and upholstery

Applications such as backpacks, furniture straps, or sofa accents require high tensile strength and abrasion resistance. Nylon and polyester are commonly chosen due to their ability to withstand repeated stress while maintaining shape and color. High-quality weaving techniques ensure that tapes do not fray or weaken over time.

Toys and children’s products

Safety and durability are critical. Materials like polyester or cotton blends are used for soft tapes, while maintaining sufficient tensile strength to prevent breakage. Non-toxic dyes and coatings are also essential for compliance with safety standards.

Industrial and export applications

For industrial applications, tapes may be exposed to moisture, chemicals, or heavy loads. Polypropylene and nylon woven ribbon tape are ideal choices, offering chemical resistance, elasticity, and long-term wear. Export goods also benefit from standardized quality inspections to ensure tapes meet international durability requirements.

Comparing materials for durability

To summarize the material considerations for woven ribbon tape, the following comparison can be made:

| Material | Tensile Strength | Abrasion Resistance | UV/Environmental Resistance | Typical Use Cases |

|---|---|---|---|---|

| Polyester | High | High | Excellent | Bags, straps, belts, decorative tapes |

| Nylon | Very high | High | Moderate (UV sensitive) | Industrial tapes, heavy-duty straps, outdoor gear |

| Cotton | Moderate | Low to Moderate | Low | Clothing trims, decorative tapes, indoor use |

| Polypropylene | Moderate | Moderate | Excellent (moisture, mildew) | Outdoor gear, eco-friendly tapes, lightweight applications |

This comparison illustrates that no single material is universally superior; selection depends on the intended application, environmental conditions, and required lifespan.

Customization and quality assurance

Companies like Fengrun Rope Weaving Co., Ltd. offer customization options for woven ribbon tape, allowing buyers to specify material type, width, thickness, color, and weaving pattern. This flexibility ensures that tapes meet specific durability requirements while aligning with aesthetic or functional goals.

Advanced production facilities and in-house testing labs enable strict quality control. Tensile strength, abrasion resistance, and colorfastness are tested systematically, guaranteeing that the final product performs as intended. This approach is essential for both polyester twill tape and multi-colored decorative woven ribbon tape, where material quality directly impacts the user experience.

Conclusion

The durability of woven ribbon tape is closely tied to material choice. Synthetic fibers such as polyester and nylon offer superior strength, abrasion resistance, and environmental resilience, making them ideal for heavy-duty or outdoor applications. Cotton provides aesthetic and tactile advantages, while polypropylene balances lightweight performance with moisture resistance.

Beyond fiber selection, weaving technique, finishing processes, and quality control play critical roles in ensuring long-lasting performance. Buyers and manufacturers should carefully evaluate these factors alongside the intended application to choose tapes that combine durability, functionality, and appearance.

By leveraging professional manufacturing expertise, high-quality materials, and advanced testing processes, woven ribbon tape can meet the diverse needs of industries ranging from fashion to industrial applications. Whether for colorful woven tape, woven ribbon tape, or polyester twill tape, selecting the right material ensures optimal performance and longevity.

English

English  中文简体

中文简体