We are a national high-tech enterprise. At present, there are many kinds of self-woven and cooperatively processed fabrics, including microfiber warp-knitted towel cloth, weft-knitted towel cloth, coral fleece, etc.

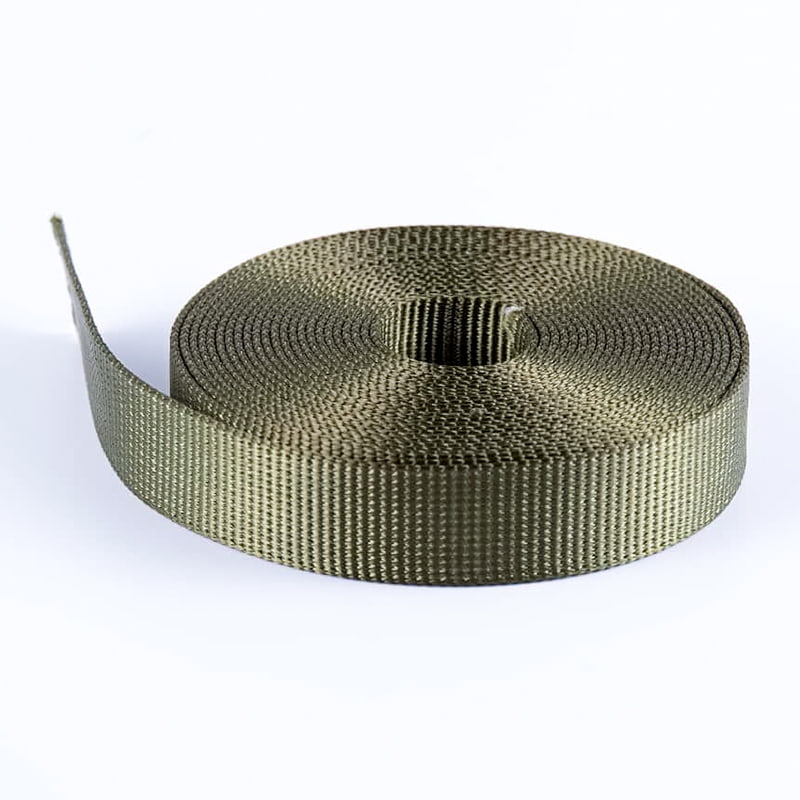

Custom Eco-friendly Nylon Webbing Straps Manufacturers

About Us

Pay attention to our latest news and exhibitions

READ OUR BLOG

-

Feb 02, 2026

What Are Decorative Jacquard Webbing Straps?

Imagine elevating a simple tote bag with a beautifully patterned handle, adding a pop of branded color to a garment's trim, or creating a unique, comfortable collar for a beloved pet. This transformative power lies in decorative jacquard webbing straps. These are not just functional straps; they are...

READ MORE -

Jan 27, 2026

The Engineering Guide to Decorative Jacquard Webbing Straps: Technical Integration and Manufacturing Excellence

In high-performance textile engineering, Decorative Jacquard Webbing Straps represent a sophisticated integration of structural durability and intricate aesthetic design. Unlike printed webbing, where patterns are applied to the surface, Jacquard weaving incorporates designs directly into the fabric...

READ MORE -

Jan 22, 2026

The Engineering Guide to Eco-friendly Nylon Webbing Straps: Material Science and Industrial Applications

The global textile industry is undergoing a paradigm shift towards circularity, placing Eco-friendly Nylon Webbing Straps at the forefront of sustainable procurement. Fengrun Rope Weaving Co., Ltd., established in 2000 in Haining, Zhejiang, has evolved alongside this movement. With over two decades ...

READ MORE

Nylon Webbing Industry Knowledge

Why Is Nylon Webbing Essential in Modern Industrial Applications?

In the global textile and industrial materials landscape, nylon webbing has established itself as an indispensable component across safety, transportation, outdoor gear, and technical applications. As production standards evolve toward strength, versatility, and sustainability, this woven structure of synthetic fibers represents a fusion of durability and innovation.

Material Composition and Structural Characteristics

Nylon webbing, also referred to as polyamide webbing, is made from continuous nylon filaments that are woven into flat or tubular structures. The polyamide molecular chain consists of strong amide bonds, giving the material excellent tensile strength and resistance to wear and fatigue. Compared with polyester or polypropylene, nylon webbing demonstrates superior elasticity, abrasion resistance, and recovery under dynamic loading, making it suitable for demanding applications such as climbing harnesses, lifting slings, and safety restraints.

The weaving structure determines the physical behavior of the strap. Woven nylon straps can be plain, twill, or tubular, each type balancing flexibility and dimensional stability differently. The tightness of the weave affects tensile modulus and elongation rate, which engineers carefully design based on application requirements. Advanced weaving processes also enhance uniformity and minimize slippage between yarns, ensuring long-term reliability in both static and dynamic systems.

Performance Advantages and Functional Attributes

The prominence of nylon webbing is largely due to its exceptional mechanical performance. It combines high tensile load capacity with flexibility, allowing it to absorb shock without deformation. Its smooth surface texture resists fraying and abrasion, even under frequent bending or environmental exposure.

In addition to mechanical resilience, polyamide webbing is also known for:

- Chemical Resistance: Stable against oils, solvents, and weak alkalis, maintaining integrity in industrial environments.

- Thermal Stability: Can endure moderate heat cycles without significant loss of strength, making it suitable for outdoor or high-friction use.

- Moisture Recovery: Although nylon absorbs some water, modern treatments reduce moisture uptake and enhance dimensional stability.

- Color Fastness: Through solution dyeing and finishing, webbing maintains vibrant color under sunlight and repeated washing.

These attributes enable nylon webbing to outperform many natural and synthetic alternatives where reliability and strength are crucial.

Sustainable Development and Eco-Friendly Manufacturing

As environmental awareness becomes a defining factor in material selection, eco-friendly nylon webbing straps have emerged as a new standard for responsible production. The transition from traditional petroleum-based nylon to recycled and bio-based fibers significantly reduces carbon footprint and resource consumption.

Haining Fengrun Rope Weaving Co., Ltd., a professional weaving enterprise specializing in ropes and webbings, has taken a leadership role in this transformation. The company integrates green manufacturing principles across sourcing, spinning, and finishing processes. By adopting recycled nylon materials and low-emission dyeing systems, Fengrun ensures that every meter of eco-friendly nylon webbing meets sustainability goals without compromising performance.

Moreover, Fengrun’s advanced equipment and strict factory management systems guarantee dimensional precision and consistent tensile performance. The company’s customization capability, supported by a strong R&D team, allows it to design and produce nylon webbings according to customer drawings or samples, ensuring tailored mechanical and aesthetic outcomes.

Through such innovations, Fengrun not only supports client-specific functional needs but also contributes to a circular economy within the textile industry.

Industrial Applications and Technical Integration

The adaptability of nylon webbing extends across multiple industries, where the balance of strength, weight, and flexibility determines product safety and usability. In automotive and aerospace engineering, polyamide webbing is employed in seat belts, cargo restraints, and tie-down systems due to its predictable load-bearing characteristics.

In sports and outdoor equipment, woven nylon straps serve as load-bearing components in backpacks, climbing harnesses, and tents. Their lightweight yet durable structure ensures both comfort and security in high-stress conditions.

In industrial safety systems, nylon webbing is incorporated into harnesses, fall-arrest systems, and lifting slings, where consistent elongation and controlled energy absorption prevent sudden impact injuries.

Beyond mechanical functions, nylon webbing’s ability to undergo various surface treatments—such as flame retardant finishing, water repellence, or reflective coating—extends its application potential. The material can also be laser-cut, stitched, or laminated with other substrates, enabling integration into composite assemblies and smart textiles.

Technological Evolution and Innovation Trends

Modern weaving and post-treatment technologies have revolutionized how nylon webbing is produced and applied. Advanced Jacquard and shuttleless looms enable complex patterning and high-speed precision weaving, while digital tension control ensures consistent yarn distribution. Finishing processes now incorporate plasma surface modification, low-temperature dyeing, and anti-UV coatings to enhance material stability under diverse conditions.

Another emerging direction is functional hybridization. Engineers are blending nylon with fibers such as aramid, spandex, or recycled polyester to achieve specific performance combinations. For instance, adding aramid increases flame resistance, while integrating spandex enhances elasticity and comfort for wearable products.

Simultaneously, sustainability innovations drive the adoption of recycled polyamide sourced from discarded fishing nets or industrial scrap. This not only reduces waste but also aligns with global environmental policies encouraging material circularity and reduced dependency on virgin polymers.

Quality Control and Standardization

In professional production environments, maintaining consistent webbing quality requires precise control of each stage—from filament extrusion to final inspection. Haining Fengrun Rope Weaving Co., Ltd. employs comprehensive testing protocols covering tensile strength, elongation rate, abrasion cycles, and color stability. Each batch undergoes dimensional analysis to verify conformity with international standards.

Strict quality assurance ensures that nylon webbing products maintain predictable mechanical properties, which is crucial for safety-critical applications. By combining statistical process control with continuous improvement systems, Fengrun achieves high reproducibility and minimal defect rates, reinforcing its reputation as a reliable global supplier.

Market Outlook and Development Direction

The global market for polyamide webbing continues to expand alongside growing demand for lightweight, durable, and sustainable materials. Sectors such as automotive safety, renewable energy, and outdoor recreation increasingly rely on high-performance webbings that combine mechanical excellence with environmental responsibility.

With the advancement of eco-friendly materials and automated production, eco-friendly nylon webbing straps are expected to replace conventional synthetic webbings in numerous applications. Customization, recyclability, and multi-functionality will define the next stage of industry development.

Haining Fengrun Rope Weaving Co., Ltd. integrates R&D, digital manufacturing, and sustainable development into a unified system. The company’s continuous pursuit of innovation and environmental responsibility reflects the future development direction of the webbing industry—high efficiency, adaptability, and environmental friendliness.

Conclusion

In summary, nylon webbing is far more than a simple woven strap; it represents a technical balance between molecular engineering, textile design, and environmental awareness. As industries demand stronger, lighter, and more sustainable materials, polyamide webbing will continue to serve as a fundamental structural medium connecting performance and responsibility.

English

English  中文简体

中文简体