We are a national high-tech enterprise. At present, there are many kinds of self-woven and cooperatively processed fabrics, including microfiber warp-knitted towel cloth, weft-knitted towel cloth, coral fleece, etc.

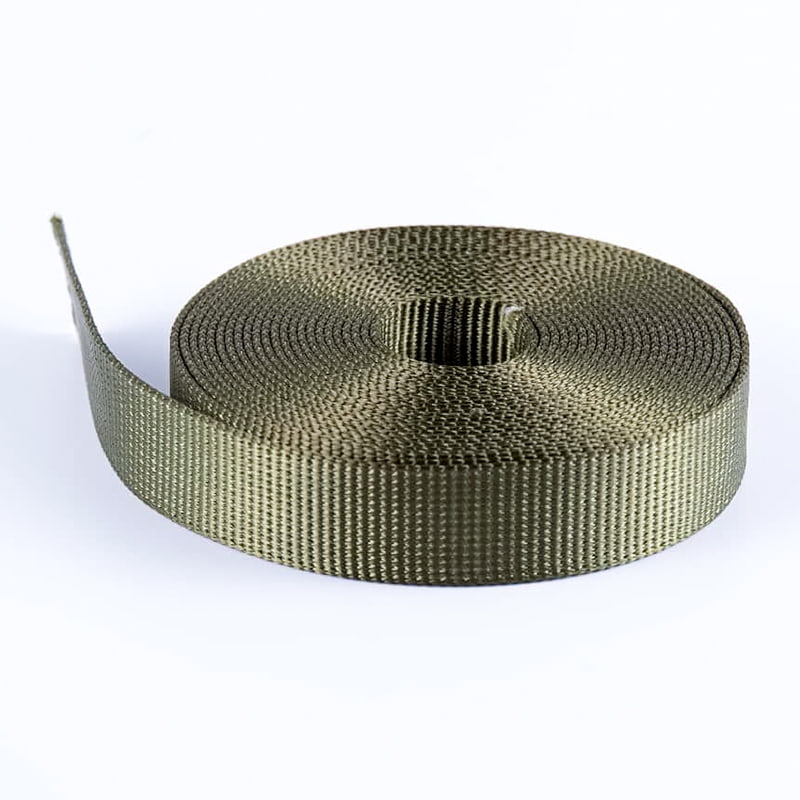

Custom Polyester Webbing Straps Manufacturers

About Us

Pay attention to our latest news and exhibitions

READ OUR BLOG

-

Feb 02, 2026

What Are Decorative Jacquard Webbing Straps?

Imagine elevating a simple tote bag with a beautifully patterned handle, adding a pop of branded color to a garment's trim, or creating a unique, comfortable collar for a beloved pet. This transformative power lies in decorative jacquard webbing straps. These are not just functional straps; they are...

READ MORE -

Jan 27, 2026

The Engineering Guide to Decorative Jacquard Webbing Straps: Technical Integration and Manufacturing Excellence

In high-performance textile engineering, Decorative Jacquard Webbing Straps represent a sophisticated integration of structural durability and intricate aesthetic design. Unlike printed webbing, where patterns are applied to the surface, Jacquard weaving incorporates designs directly into the fabric...

READ MORE -

Jan 22, 2026

The Engineering Guide to Eco-friendly Nylon Webbing Straps: Material Science and Industrial Applications

The global textile industry is undergoing a paradigm shift towards circularity, placing Eco-friendly Nylon Webbing Straps at the forefront of sustainable procurement. Fengrun Rope Weaving Co., Ltd., established in 2000 in Haining, Zhejiang, has evolved alongside this movement. With over two decades ...

READ MORE

Polyester Webbing Industry Knowledge

How Does Woven Polyester Strap Deliver Strength and Stability?

In the evolving landscape of synthetic fiber applications, polyester webbing has become a cornerstone material across multiple sectors, valued for its balance of durability, flexibility, and resistance to environmental stress. As industries increasingly seek sustainable and high-performance materials, woven polyester strap technology continues to advance, merging mechanical strength with ecological responsibility.

Structural Characteristics of Polyester Webbing

Polyester webbing is a textile strip woven from polyethylene terephthalate (PET) fibers, engineered for superior tensile strength and controlled elasticity. Its defining characteristic lies in its woven construction, which provides uniform stress distribution and resistance to abrasion. The typical woven polyester strap exhibits high dimensional stability—meaning it retains shape and load integrity under prolonged tension—making it suitable for safety-critical or load-bearing uses.

The internal structure of polyester fibers, consisting of tightly oriented crystalline regions, contributes to the material’s high tensile modulus. This microstructure ensures minimal deformation under pressure, offering a dependable combination of strength and flexibility. Furthermore, the surface texture of the webbing can be customized through different weaving patterns—such as plain, twill, or herringbone—to meet diverse mechanical and aesthetic needs.

Performance Advantages and Mechanical Reliability

One of the reasons durable polyester belt products dominate in industrial and commercial applications is their balanced mechanical performance. Compared with other synthetic fibers, polyester webbing straps demonstrate:

- High Tensile Strength: Able to support substantial loads without rupture, ideal for lifting, towing, or safety gear.

- Abrasion and UV Resistance: The molecular stability of polyester resists degradation from friction and sunlight, ensuring long service life in outdoor conditions.

- Low Moisture Absorption: Polyester webbing maintains strength and flexibility even in humid or wet environments, minimizing stretch or weakening.

- Temperature Stability: Polyester retains its mechanical integrity within a wide temperature range, providing consistent performance from subzero to moderately high heat conditions.

In essence, these properties define the woven polyester strap as both lightweight and structurally resilient—qualities that make it a preferred choice in safety harnesses, luggage straps, industrial lifting slings, and pet accessories.

Production Technology and Quality Control

The production of polyester webbing integrates precision weaving and finishing processes that determine both performance and aesthetics. Haining Fengrun Rope Weaving Co., Ltd. employs advanced technologies such as automated looms, tension control systems, and computer-aided pattern management to ensure consistency in mass production.

At Fengrun, quality control forms a core operational principle. The company maintains its own testing laboratory equipped with advanced inspection systems to monitor parameters like tensile strength, color fastness, elongation rate, and abrasion resistance. This integrated approach ensures that every durable polyester belt leaving the facility meets strict technical specifications and international safety standards.

Moreover, the precision finishing stage—comprising dyeing, heat setting, and surface coating—enhances both visual appeal and material performance. Through these techniques, polyester webbing straps achieve consistent color stability and dimensional uniformity even after long-term exposure or repeated mechanical stress.

Sustainability and Eco-Friendly Production Practices

As global manufacturing shifts toward environmentally conscious models, polyester webbing production is increasingly tied to sustainable initiatives. Although polyester originates from petrochemical sources, advanced recycling technologies now enable recycled polyester (rPET) fibers to play a central role in the webbing industry.

Haining Fengrun Rope Weaving Co., Ltd. actively integrates sustainability into its operations. The company specializes not only in conventional woven polyester strap production but also in eco-friendly nylon webbing made from recycled materials. By adopting low-carbon manufacturing processes and energy-efficient equipment, Fengrun reduces its environmental footprint while maintaining high product reliability.

The company’s philosophy—“From sourcing to production, we uphold green practices”—illustrates its commitment to circular economy principles. Through these efforts, Fengrun assists global clients in achieving their own sustainability goals, providing recyclable and long-lasting polyester webbing solutions that minimize waste throughout the product lifecycle.

Versatility Across Industrial and Consumer Fields

The adaptability of polyester webbing stems from its capacity to meet varied functional requirements. Its mechanical performance, color customization, and cost efficiency allow it to serve numerous industries, including:

- Automotive and Transport: Used in seat belts, cargo tie-downs, and restraint systems where consistent tensile reliability is critical.

- Outdoor and Recreation: Applied in climbing harnesses, camping gear, and marine ropes due to its UV and moisture resistance.

- Apparel and Accessories: Forms the structural base of belts, bags, and footwear, valued for both strength and aesthetic versatility.

- Pet Products: A key component in webbing for pet leashes and collars, combining comfort with controlled flexibility.

- Industrial Use: Common in lifting straps, safety harnesses, and composite reinforcement, where load-bearing capability is essential.

In each domain, durable polyester belt products maintain a consistent advantage: long-term reliability under mechanical and environmental stress without compromising user safety or appearance.

Technical Differentiation and Product Diversity

A distinguishing feature of polyester webbing straps are its multiformity—the ability to produce diverse specifications through controlled variation in fiber denier, weaving density, and surface treatment. Fengrun’s production line encompasses a wide range of synthetic webbing products, including polypropylene, polyester, cotton, and nylon, tailored to meet application-specific demands.

Color and width customization enhance not only function but also brand identity. For example, colorfast dyeing ensures enduring visual consistency for commercial branding, while heat treatment stabilizes dimensions and enhances smoothness. Such engineering flexibility allows polyester webbing straps to integrate seamlessly into complex design systems across industries.

Quality Assurance and Performance Testing

Reliable polyester webbing manufacturing relies on comprehensive quality verification systems. At Fengrun, rigorous testing ensures compliance with both domestic and international standards. Quality assessment includes:

- Tensile and Elongation Testing for load-bearing capacity;

- Abrasion and Tear Resistance Evaluation to simulate real-use wear;

- UV and Colorfastness Testing for outdoor durability;

- Chemical and Thermal Resistance Assessment to ensure compatibility with diverse operational environments.

By integrating these validation processes, Fengrun guarantees consistent mechanical performance across all batches. This systematic quality assurance not only builds client confidence but also reinforces the global reputation of woven polyester strap products as dependable and cost-effective solutions.

Market Trends and Future Development

The global market for polyester webbing continues to evolve alongside technological innovation and environmental policy. Key trends shaping its future include:

- Shift Toward Recycled Materials: The adoption of post-consumer recycled polyester supports global sustainability mandates.

- Integration with Smart Textiles: Emerging developments aim to embed sensors or RFID tags into webbing for tracking or monitoring purposes.

- Lightweight Engineering: Refinements in fiber structure and weaving density enhance performance-to-weight ratios.

- Automation and Digitalization: Advanced weaving systems with real-time feedback improve production precision and reduce waste.

Conclusion: Why Polyester Webbing Remains Indispensable

In summary, polyester webbing represents a critical material foundation bridging industrial performance and environmental responsibility. Its combination of high tensile strength, weather resistance, design adaptability, and sustainability potential makes it an enduring solution for diverse applications—from safety gear to consumer products.

English

English  中文简体

中文简体