We are a national high-tech enterprise. At present, there are many kinds of self-woven and cooperatively processed fabrics, including microfiber warp-knitted towel cloth, weft-knitted towel cloth, coral fleece, etc.

Custom Polypropylene Tubular Webbing Manufacturers

About Us

Pay attention to our latest news and exhibitions

READ OUR BLOG

-

Feb 02, 2026

What Are Decorative Jacquard Webbing Straps?

Imagine elevating a simple tote bag with a beautifully patterned handle, adding a pop of branded color to a garment's trim, or creating a unique, comfortable collar for a beloved pet. This transformative power lies in decorative jacquard webbing straps. These are not just functional straps; they are...

READ MORE -

Jan 27, 2026

The Engineering Guide to Decorative Jacquard Webbing Straps: Technical Integration and Manufacturing Excellence

In high-performance textile engineering, Decorative Jacquard Webbing Straps represent a sophisticated integration of structural durability and intricate aesthetic design. Unlike printed webbing, where patterns are applied to the surface, Jacquard weaving incorporates designs directly into the fabric...

READ MORE -

Jan 22, 2026

The Engineering Guide to Eco-friendly Nylon Webbing Straps: Material Science and Industrial Applications

The global textile industry is undergoing a paradigm shift towards circularity, placing Eco-friendly Nylon Webbing Straps at the forefront of sustainable procurement. Fengrun Rope Weaving Co., Ltd., established in 2000 in Haining, Zhejiang, has evolved alongside this movement. With over two decades ...

READ MORE

Polypropylene Hollow Webbing Industry Knowledge

Why Choose Polypropylene Hollow Webbing for Industrial Applications?

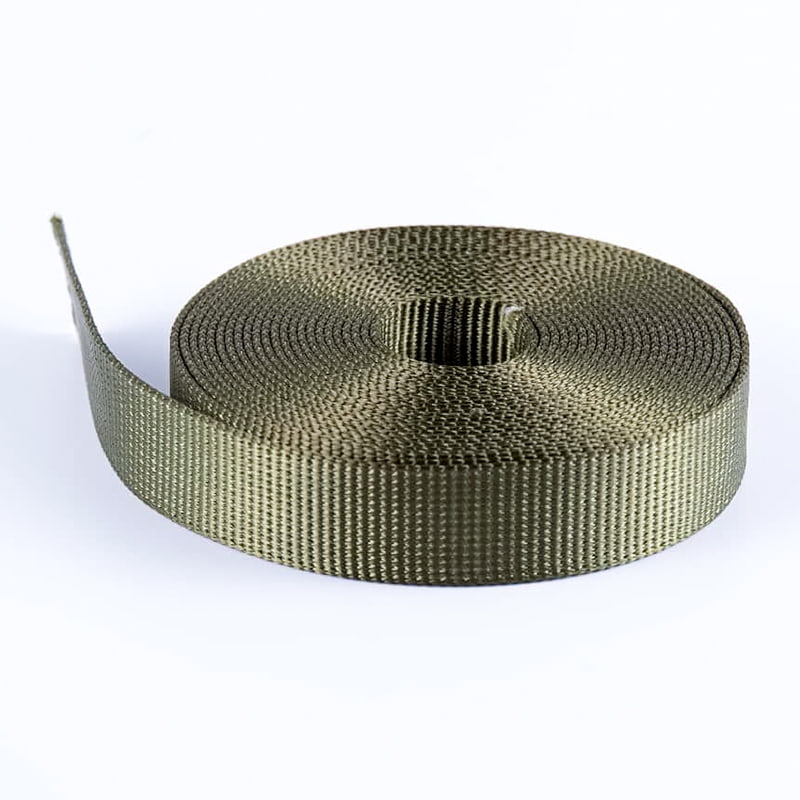

In contemporary material engineering, polypropylene hollow webbing has emerged as a critical structural and functional component across a broad range of industries. Known for its lightweight, tensile strength, and resistance to environmental stress, this category of synthetic webbing—also referred to as polypropylene tubular webbing—has become indispensable in sectors such as safety gear, luggage, furniture, and outdoor equipment.

Material Composition and Structural Advantages

Polypropylene hollow webbing is produced through high-density weaving of polypropylene fibers, forming a tubular or hollow internal structure. This configuration significantly enhances its flexibility and strength-to-weight ratio, allowing the webbing to sustain dynamic loads without deformation. Compared to solid webbing, the hollow form offers better compressive resistance and improved softness, making it suitable for products that require ergonomic performance and comfort.

The inherent properties of polypropylene—such as its chemical inertness, hydrophobicity, and resistance to UV exposure—further enhance its long-term stability. It resists corrosion from moisture, acids, and alkaline solutions, extending product life under outdoor or marine conditions. These characteristics make polypropylene tubular webbing particularly useful in outdoor furniture, marine ropes, climbing harnesses, and luggage accessories where durability and resilience are paramount.

Manufacturing Process and Quality Control

The production of polypropylene hollow webbing involves several key steps: fiber extrusion, weaving, heat setting, and post-treatment. Each phase determines the final product’s physical integrity and performance precision. Advanced looms and digital control systems are used to ensure uniform density and tight weaving patterns, avoiding internal stress points that could compromise the webbing’s structure.

Haining Fengrun Rope Weaving Co., Ltd. is a professional manufacturer of ropes and webbing products. The company utilizes automated production lines and modern weaving technology to ensure product consistency. A dedicated R&D department can customize webbing styles, tensile strength grades, and sizes according to specific customer needs. Strong laboratory capabilities and comprehensive testing equipment ensure that every polypropylene webbing meets international quality standards.

Performance and Application Scenarios

Polypropylene tubular webbing is distinguished by its combination of mechanical performance and cost efficiency. Its high elongation at break and excellent recovery rate allow it to absorb energy effectively, reducing stress on connected components. This makes it ideal for securing systems, reinforcement applications, and dynamic environments.

In industrial safety equipment, it is used in load-bearing harnesses and lifting slings due to its excellent weight-to-strength ratio. In consumer products, the material is favored for bag straps, belts, and sports accessories, where flexibility and aesthetic versatility are key. The hollow design permits easy insertion of cords or reinforcements, enhancing both functionality and appearance.

Beyond mechanical use, polypropylene hollow webbing’s chemical stability enables it to perform in environments exposed to oils, solvents, or temperature fluctuations. Its low water absorption ensures dimensional stability, maintaining consistent performance even under wet or humid conditions.

Sustainability and Eco-Friendly Production

The environmental advantages of polypropylene are increasingly relevant in today’s manufacturing climate. The polymer is fully recyclable, and its production requires less energy compared to many alternatives. Haining Fengrun Rope Weaving Co., Ltd. integrates sustainability at every stage—from raw material selection to process optimization. The company employs recycled polypropylene fibers and low-carbon manufacturing techniques to minimize ecological impact.

By adhering to green production principles, Fengrun supports customers’ environmental compliance and corporate sustainability initiatives. Its polypropylene webbing straps combine durability with recyclability, providing a responsible solution for industries seeking reduced carbon footprints without compromising on product performance.

Customization and Design Flexibility

One of the defining advantages of polypropylene hollow webbing lies in its adaptability. Through advanced weaving and dyeing technologies, it can be manufactured in diverse colors, textures, and widths. This flexibility allows designers to integrate both technical and aesthetic functions into their products.

Fengrun’s customization capabilities reflect the industry’s evolving needs. The company’s R&D team collaborates closely with clients, developing new patterns or structures based on drawings or physical samples. This ensures each polypropylene tubular webbing aligns precisely with its intended application—whether that involves abrasion resistance for industrial straps or softness and vivid color for consumer goods.

Moreover, Fengrun’s production diversity extends beyond polypropylene to include polyester, cotton, and nylon webbing, offering integrated solutions for multi-material applications. This comprehensive approach enhances competitiveness in both domestic and international markets.

Economic and Industrial Competitiveness

From a manufacturing standpoint, polypropylene hollow webbing delivers substantial economic advantages. The polymer’s relatively low cost, combined with its high yield-to-weight ratio, allows producers to achieve efficient material utilization. This translates into cost-effective production without sacrificing mechanical integrity.

Fengrun emphasizes operational efficiency throughout its workflow. From order confirmation to delivery, its streamlined processes and rigorous quality control ensure quick turnaround times. This competitive speed, coupled with dependable quality, positions the company as a reliable supplier in the global webbing market. Its emphasis on punctual delivery and customer collaboration enhances long-term business stability, which is essential in a fast-paced industrial environment.

Future Development and Technological Outlook

The future of polypropylene webbing straps lies in performance optimization and sustainable material innovation. As regulatory standards for recyclability tighten, research continues into bio-based polypropylene and additive-modified polymers that further reduce environmental impact while improving tensile performance and heat resistance.

Automation and intelligent production are also reshaping the webbing industry. Smart looms capable of real-time monitoring and quality feedback minimize waste and enhance precision. Additionally, hybrid weaving technologies are expanding the scope of polypropylene hollow webbing applications. By combining polypropylene with high-modulus fibers such as aramid or polyester, manufacturers can achieve specific strength or elasticity targets, opening opportunities in automotive, aerospace, and medical device fields.

Conclusion

Polypropylene hollow webbing exemplifies the convergence of material science, industrial precision, and environmental awareness. Its structural integrity, chemical stability, and design flexibility make it an essential component in both industrial and consumer applications. As industries demand lighter, stronger, and greener materials, polypropylene tubular webbing continues to demonstrate its relevance and adaptability.

English

English  中文简体

中文简体