We are a national high-tech enterprise. At present, there are many kinds of self-woven and cooperatively processed fabrics, including microfiber warp-knitted towel cloth, weft-knitted towel cloth, coral fleece, etc.

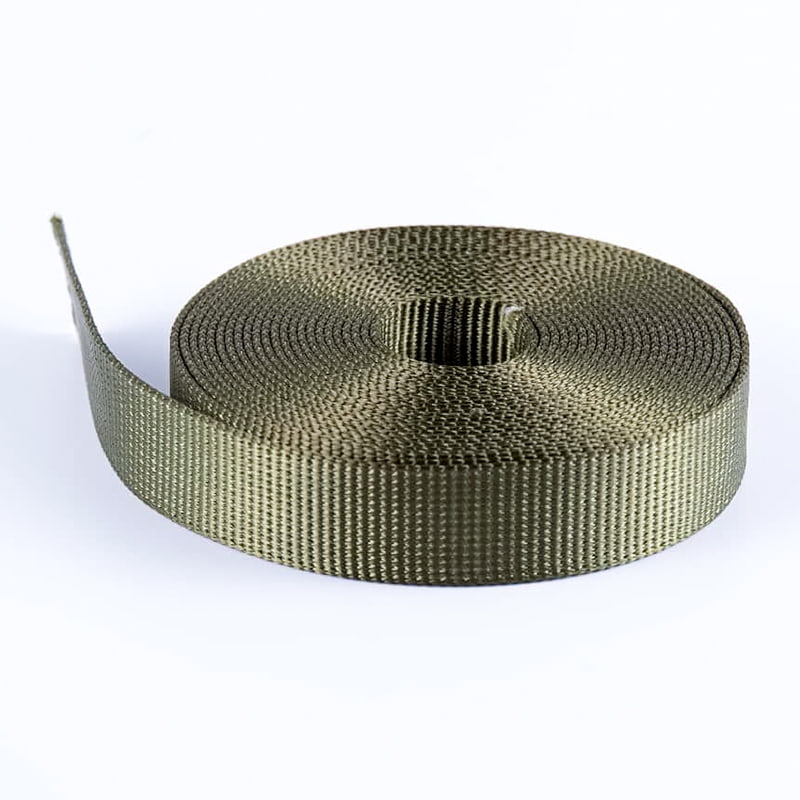

Custom Cotton Webbing for Pet Training Leashes Manufacturers

About Us

Pay attention to our latest news and exhibitions

READ OUR BLOG

-

Feb 02, 2026

What Are Decorative Jacquard Webbing Straps?

Imagine elevating a simple tote bag with a beautifully patterned handle, adding a pop of branded color to a garment's trim, or creating a unique, comfortable collar for a beloved pet. This transformative power lies in decorative jacquard webbing straps. These are not just functional straps; they are...

READ MORE -

Jan 27, 2026

The Engineering Guide to Decorative Jacquard Webbing Straps: Technical Integration and Manufacturing Excellence

In high-performance textile engineering, Decorative Jacquard Webbing Straps represent a sophisticated integration of structural durability and intricate aesthetic design. Unlike printed webbing, where patterns are applied to the surface, Jacquard weaving incorporates designs directly into the fabric...

READ MORE -

Jan 22, 2026

The Engineering Guide to Eco-friendly Nylon Webbing Straps: Material Science and Industrial Applications

The global textile industry is undergoing a paradigm shift towards circularity, placing Eco-friendly Nylon Webbing Straps at the forefront of sustainable procurement. Fengrun Rope Weaving Co., Ltd., established in 2000 in Haining, Zhejiang, has evolved alongside this movement. With over two decades ...

READ MORE

Webbing for Pet Leash Industry Knowledge

What Determines the Performance and Sustainability of Webbing for Pet Leash?

In the rapidly evolving pet accessories market, webbing for pet leads plays a pivotal role in balancing durability, comfort, and environmental responsibility. As global demand for high-quality, sustainable pet products continues to grow, manufacturers and consumers alike are paying closer attention to the materials, weaving techniques, and production ethics behind these essential components. Understanding the technical and ecological dimensions of webbing is therefore crucial for selecting products that meet both performance expectations and sustainability standards.

The Functional Foundation of Pet Lead Webbing

The webbing used for pet leads serves as the structural backbone of the product, determining not only strength but also safety and comfort. Unlike simple textile straps, webbing for pet leash must withstand high tensile loads, resist abrasion, and maintain flexibility across a range of environmental conditions. This requires precise control of raw material selection, fiber treatment, and weaving density.

From a mechanical standpoint, three performance factors dominate: tensile strength, elongation rate, and surface texture. High tensile strength ensures that the webbing can endure sudden pulls without deformation. Moderate elongation contributes to shock absorption, protecting both the animal and handler. Meanwhile, an optimal surface texture prevents frictional damage to the pet’s fur or skin while maintaining sufficient grip for control.

Material Selection: Balancing Strength, Comfort, and Ecology

Material choice fundamentally shapes the properties of pet leash webbing. Among the most common fibers—nylon, cotton, and leather—each offers distinct advantages and trade-offs.

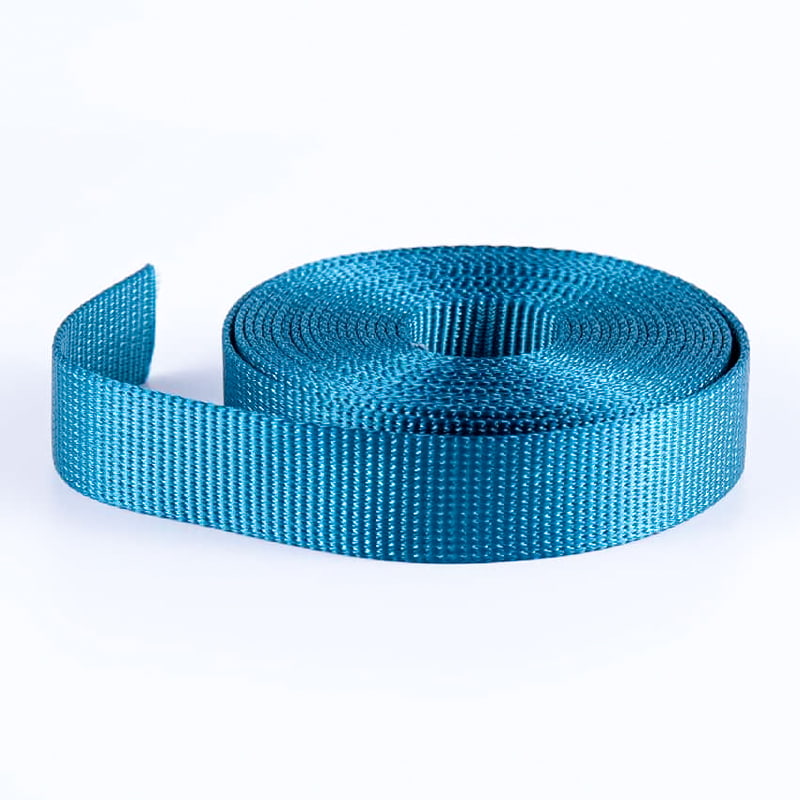

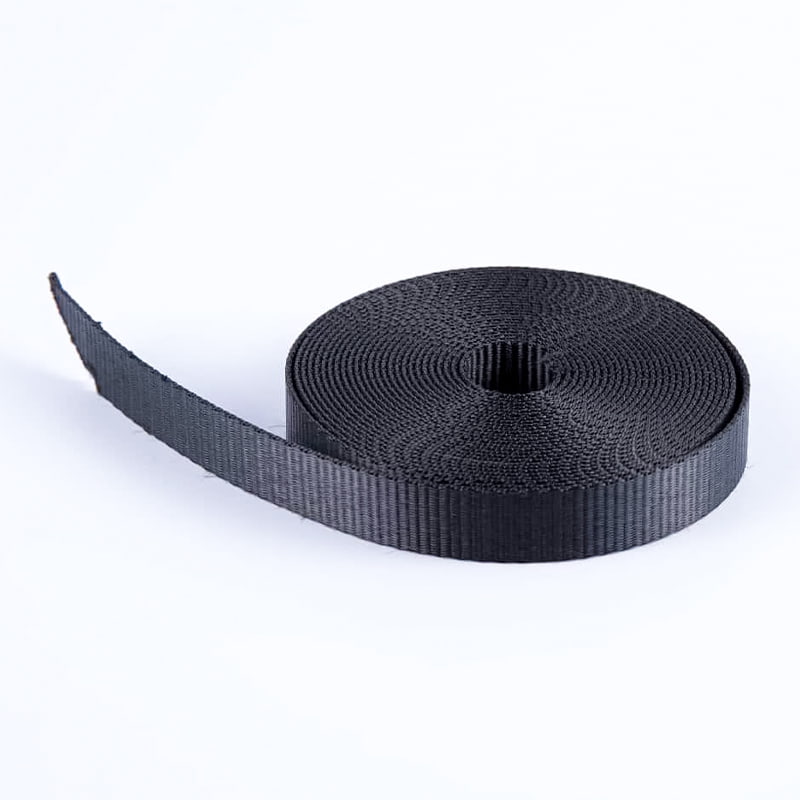

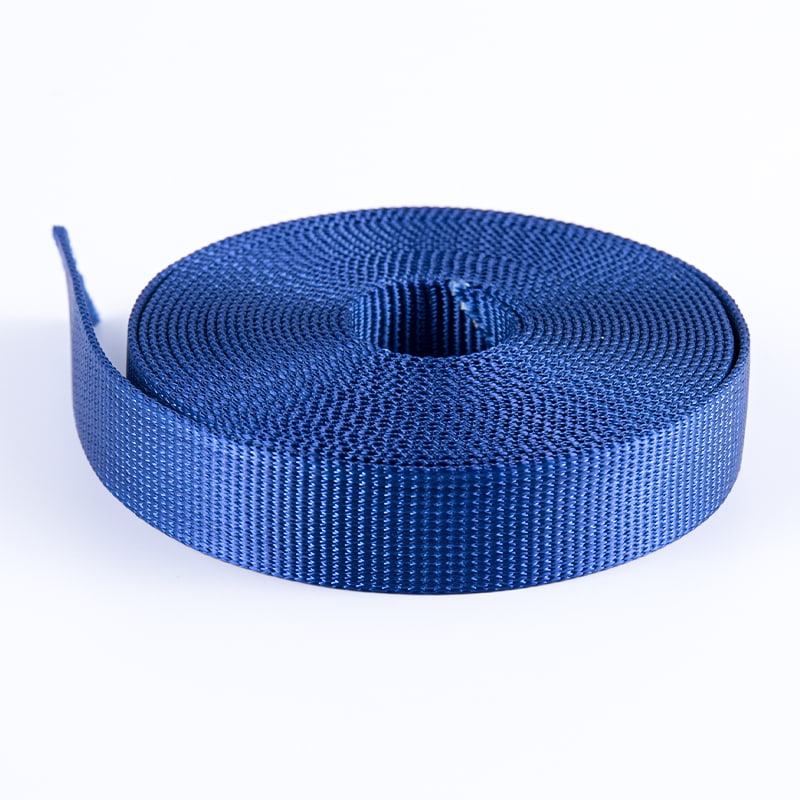

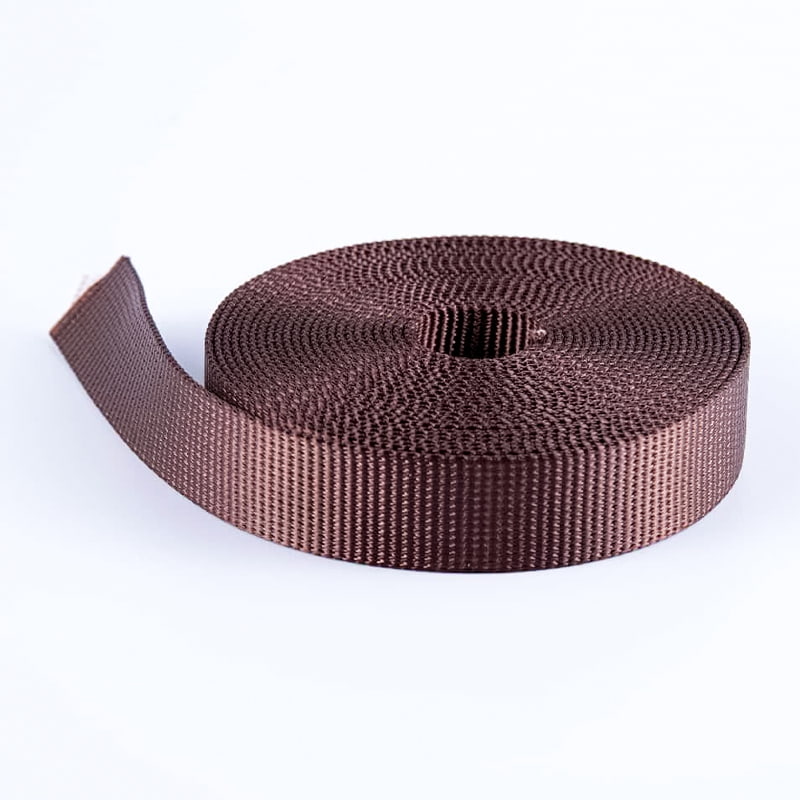

(1) Nylon Webbing:

Nylon is the most widely used material in modern pet leads due to its combination of strength, resilience, and water resistance. It offers excellent load-bearing performance and flexibility, maintaining structural integrity even under wet or humid conditions. Moreover, nylon webbing can be dyed in vivid colors and customized in various widths and thicknesses, making it ideal for aesthetic and branding purposes. Recent advancements in eco-friendly nylon, such as recycled variants, further enhance its environmental compatibility.

(2) Cotton Webbing:

Cotton webbing appeals to markets that prioritize comfort and natural fibers. Its soft handfeel makes it gentle on pets’ skin, reducing chafing and irritation. While cotton lacks the tensile strength of nylon, it excels in breathability and biodegradability, making it suitable for eco-conscious consumers. To overcome moisture absorption issues, some manufacturers treat cotton webbing with water-repellent finishes or blend it with synthetic fibers for enhanced durability.

(3) Leather Webbing:

Leather remains a premium material choice, favored for its aesthetic appeal, tactile quality, and long-term wear resistance. It provides a traditional and luxurious feel, often associated with high-end pet accessories. However, leather webbing requires careful processing and maintenance to ensure flexibility and prevent cracking. Sustainable sourcing and vegetable-tanning methods are increasingly emphasized to align with environmental expectations.

(4) Advanced Synthetic and Hybrid Materials:

In addition to conventional fibers, the market has embraced high-performance synthetics such as polyester and polypropylene. These materials offer excellent UV resistance and low moisture absorption. Hybrid weaves—combining nylon strength with cotton comfort or synthetic durability—reflect the industry’s movement toward multifunctional solutions.

Weaving Technology and Structural Innovation

The functionality of webbing for pet leads extends beyond material selection; weaving architecture is equally critical. Variations such as plain, twill, or tubular weaves each influence flexibility, grip, and edge resistance.

Plain weave provides balanced strength and smoothness, suitable for standard applications. Twill weave offers superior flexibility and texture variation, while tubular weave enhances tensile load distribution, preventing edge fraying and improving hand comfort. The integration of multi-filament yarns, micro-pattern reinforcement, and double-layer construction further enhances mechanical stability and aesthetic diversity.

Modern weaving machinery enables precision control of tension, density, and pattern, ensuring consistency in every meter of webbing. High-speed looms coupled with digital monitoring systems optimize production efficiency while minimizing waste—a key component in sustainable manufacturing.

Surface Treatment and Functional Enhancement

After weaving, finishing treatments determine the webbing’s performance in practical use. Techniques such as heat setting, resin coating, UV stabilization, and anti-fray edge sealing strengthen the webbing’s resistance to wear, deformation, and environmental stress.

Surface finishing also enhances visual appeal. Printing, embossing, or reflective coatings not only enrich product design but also add safety features—particularly valuable for night-time walking. Water- and stain-resistant finishes extend product lifespan, reducing replacement frequency and overall environmental footprint.

Sustainability and Eco-Responsible Manufacturing

Environmental stewardship is now a defining factor in evaluating modern pet leash webbing. From raw material sourcing to waste management, sustainability principles influence every production stage.

Haining Fengrun Rope Weaving Co., Ltd. exemplifies this shift toward green manufacturing. As a professional weaving enterprise specializing in ropes and webbings, Fengrun emphasizes eco-friendly nylon webbing made from recycled materials through low-carbon processes. The company’s integrated production system minimizes energy consumption, optimizes water recycling, and reduces emissions, ensuring that durability and ecological responsibility coexist.

By adopting advanced looms, strict factory management, and innovative production concepts, Fengrun delivers high-performance webbing products that align with global sustainability goals. Its focus on quality, customization, and diversification allows partners to select environmentally sound yet versatile solutions across a range of applications. In the broader context, the industry’s move toward recycled polymers, bio-based coatings, and closed-loop recycling systems demonstrates a commitment to responsible production.

Customization and Aesthetic Trends

Customization defines the modern webbing market. Pet owners increasingly demand leads that reflect individual style and comfort preferences. Color variety, printed patterns, and personalized branding have become integral to product differentiation.

For manufacturers, this trend translates into multi-dimensional design flexibility—offering adjustable thickness, texture, and elasticity tailored to specific pet breeds or activities. High-end webbing can integrate reflective threads, antimicrobial coatings, or ergonomic padding, creating value-added performance features.

Fengrun’s production capabilities, supported by advanced dyeing and finishing technology, enable high-definition color rendering and long-lasting print stability. These attributes cater to both OEM clients and direct brand orders seeking quality assurance and creative freedom.

Quality Assurance and International Standards

Given that webbing for pet training leashes directly impacts safety, stringent quality control is essential. Testing typically involves assessments of tensile strength, colorfastness, abrasion resistance, and environmental compliance.

International standards such as ISO 9001 and REACH govern consistency and chemical safety. Haining Fengrun Rope Weaving Co., Ltd. employs end-to-end inspection—covering raw material verification, process monitoring, and final tensile testing—to ensure product reliability. This systematic approach not only maintains product integrity but also strengthens global competitiveness.

The Future of Webbing for Pet Leads: Toward Intelligent and Green Manufacturing

The next phase of development in webbing for pet leads will likely merge digital innovation with sustainability. Intelligent weaving systems capable of monitoring yarn tension and defect detection are already transforming production efficiency. Material science advancements—such as biodegradable synthetics and graphene-reinforced fibers—promise to redefine durability and environmental performance.

Moreover, as consumers increasingly value transparency, traceable supply chains and carbon-footprint labeling will become standard practice. Manufacturers that can integrate eco-design principles, smart process control, and global sustainability certification will lead the market transformation.

Haining Fengrun Rope Weaving Co., Ltd. continues to expand in this direction, combining technological modernization with green responsibility. Its mission aligns with the growing call for eco-friendly, durable, and customizable webbing solutions that support both consumer needs and environmental protection.

Conclusion

The performance and sustainability of webbing for pet training leashes are determined by a precise balance of material science, structural engineering, and environmental ethics. From nylon’s strength to cotton’s softness and leather’s prestige, each fiber contributes unique advantages that can be optimized through advanced weaving and finishing techniques.

English

English  中文简体

中文简体