We are a national high-tech enterprise. At present, there are many kinds of self-woven and cooperatively processed fabrics, including microfiber warp-knitted towel cloth, weft-knitted towel cloth, coral fleece, etc.

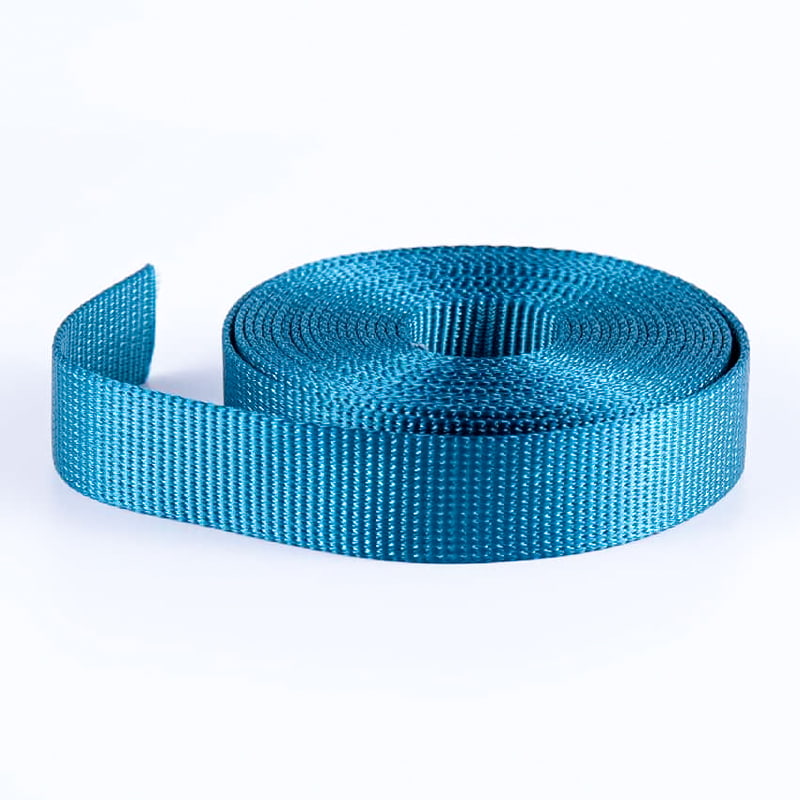

Understanding Polyester Webbing: The Modern Workhorse Material

represent one of the most versatile and reliable engineered textile solutions across global industries. Made from polyethylene terephthalate (PET) fibers, either virgin or recycled, polyester webbing is manufactured through a precise process of extrusion, spinning, and high-density weaving. The resulting material exhibits an exceptional balance of properties that synthetic alternatives struggle to match. Its molecular structure provides high tensile strength with minimal stretch, excellent resistance to UV radiation and most chemicals, and low moisture absorption. These inherent characteristics make it the go-to choice for applications where long-term durability, dimensional stability, and colorfastness are non-negotiable, from securing cargo on container ships to the subtle strap on a luxury handbag.

The dominance of polyester in the webbing market is no accident. Its performance profile is consistently predictable, which is critical for engineering and safety applications. For a manufacturer with decades of experience like Haining Fengrun Rope Weaving Co., Ltd., mastering the production of polyester webbing means controlling every variable—from the denier of the yarn to the tension on the loom—to produce straps that meet exacting international standards for strength and durability, supporting its widespread use in export goods across continents.

Key Properties: Strength, UV Resistance, and Durability

The superiority of polyester webbing is defined by a combination of key technical properties that directly translate to real-world performance and cost-effectiveness over a product's lifecycle.

- High Tensile Strength & Low Elongation: Polyester fibers are incredibly strong for their weight and exhibit very little permanent stretch under load (typically 10-15% at break). This ensures that straps remain tight and secure, providing reliable restraint without needing frequent re-tightening.

- Superior UV & Weather Resistance: Polyester has excellent inherent resistance to degradation from sunlight, making it ideal for outdoor applications like tie-downs, tent guylines, and outdoor furniture where nylon would weaken significantly over time.

- Chemical & Mildew Resistance: It is unaffected by most common chemicals, salts, and mildew, ensuring longevity in harsh industrial or marine environments. Its low moisture absorption (approx. 0.4%) prevents rot and weight gain.

- Excellent Colorfastness: Polyester can be easily solution-dyed, meaning color is added to the polymer melt before the fiber is extruded. This results in vibrant, fade-resistant colors that last the life of the webbing.

Critical Applications Across Industries

The utility of polyester webbing straps spans from heavy industry to consumer fashion, a testament to their adaptability. In logistics and transportation, they are the backbone of cargo securement, valued for their strength and resistance to abrasion against rough surfaces. In the outdoor and sports industry, their UV stability and moisture resistance make them perfect for backpacks, climbing harnesses, and camping gear. The furniture industry relies on them for durable, colorfast support straps in sofas and chairs. Furthermore, in apparel and luggage, polyester webbing provides a stable, non-stretching base for bag handles and garment straps, where consistency is key. This cross-industry reliance underscores the importance of partnering with a manufacturer capable of producing webbing to the precise specifications demanded by each unique application, ensuring performance and safety are never compromised.

For Outdoor and Automotive Use: UV-Resistant Tie-Down Straps

One of the most demanding applications is in the realm of tie-downs for securing loads on trailers, trucks, and roof racks. For this, UV-resistant polyester tie-down webbing is the industry standard. Unlike nylon, which can lose up to 20% of its strength when continuously exposed to sunlight, polyester maintains its integrity. This UV resistance, combined with its minimal stretch, ensures a load stays securely fastened over long distances and varying weather conditions. High-quality versions feature a tightly woven, abrasion-resistant face and are often finished with coatings to enhance grip and protect against dirt and grime. When sourcing these critical components, the webbing's breaking strength, working load limit, and compliance with transportation regulations are paramount considerations.

In Furniture and Apparel: Durable Polyester Webbing for Longevity

In the furniture and interior design sector, durable polyester webbing serves as the hidden foundation for comfort. Used as the supportive lattice in sofa and chair frames, it must withstand years of cyclic loading without sagging or degrading. Its low stretch property is crucial here, maintaining seat support over time. In apparel and bags, polyester webbing is prized for its stability. It provides a solid, non-elastic anchor for bag handles and backpack straps, ensuring the product maintains its shape and the handles don't stretch over time. The availability of a wide color range, a core offering of manufacturers like Fengrun, allows designers to match or contrast webbing precisely with their product's aesthetic, from bold, vibrant tones to subtle neutrals.

| Application Sector | Primary Requirement | How Polyester Webbing Excels |

| Transportation & Logistics | High strength, low stretch, abrasion resistance. | Maintains tension, resists wear from cargo, UV stable for outdoor exposure. |

| Outdoor & Sports Gear | Weather/UV resistance, durability, lightweight. | Does not degrade in sun or rain, strong for its weight, dries quickly. |

| Furniture Manufacturing | Minimal creep (permanent stretch), long-term load-bearing. | Provides lasting support without sagging, available in neutral colors for upholstery. |

| Luggage & Apparel | Dimensional stability, colorfastness, aesthetic variety. | Handles remain a consistent length, colors stay vibrant, wide range of colors/widths. |

| Safety & Fall Protection | Predictable strength, energy absorption (in specific weaves), durability. | Consistent performance under load, resistant to environmental degradation. |

Customization and Sustainable Options

The modern market demands more than just standard products. The ability to create custom polyester webbing straps is a significant advantage for brands. Customization can include specific widths (from 10mm to 100mm+), unique colors achieved through solution dyeing, printed patterns or logos, and special finishes like fire retardancy or water resistance. Beyond customization, sustainability is a driving trend. The industry is increasingly moving towards recycled polyester (rPET) webbing, made from post-consumer plastic bottles. This material offers nearly identical performance characteristics to virgin polyester but with a drastically reduced environmental footprint, appealing to eco-conscious brands and consumers. Manufacturers at the forefront, guided by principles of innovation, are investing in the technology to produce high-quality rPET webbing, meeting both performance specs and green mandates.

Sourcing from a Professional Webbing Manufacturer

Not all webbing is created equal. Sourcing polyester webbing straps from a dedicated professional manufacturer like Haining Fengrun Rope Weaving Co., Ltd. ensures access to expertise and consistent quality. A professional manufacturer controls the entire process, from polymer chip selection to final rolling and inspection. They maintain strict quality control protocols, testing for breaking strength, color consistency, and weave uniformity. Their technical team can advise on the optimal weave type (plain, twill, herringbone) for an application, balancing flexibility and strength. Furthermore, they have the capacity to handle custom orders based on samples, replicating existing products or developing new ones to precise specifications, which is invaluable for product development and maintaining supply chain integrity for export-oriented businesses.

FAQ

What is the difference between polyester and nylon webbing?

Polyester and nylon are the two most common synthetic webbings, but they have distinct profiles. The core difference lies in their reaction to moisture and stretch. Polyester webbing has very low moisture absorption (≈0.4%) and minimal stretch, making it stable in humid/wet conditions and ideal for applications where tight security is needed (tie-downs, furniture). Nylon webbing absorbs more moisture (up to 4-8%), which causes it to swell and lose about 10-15% of its strength when wet, but it regains it when dry. Nylon has higher elasticity (it stretches more), which can be an advantage for absorbing shock loads, as in climbing ropes. For UV resistance and colorfastness, polyester is generally superior.

How is the strength of polyester webbing measured and rated?

The strength of polyester webbing straps is scientifically measured and rated to ensure safety. The key metric is the Breaking Strength (or Ultimate Tensile Strength), which is the maximum load the webbing can withstand in a single pull to destruction, tested according to standards like EN 1492 or AS/NZS 4385. More important for users is the Working Load Limit (WLL), which is the maximum recommended load during routine use. The WLL is typically calculated as 1/5th to 1/10th of the Breaking Strength, providing a significant safety factor. Reputable manufacturers provide these ratings for their products. Width and thickness directly influence strength; a 2-inch wide, heavy-duty webbing will have a much higher WLL than a 1-inch lightweight version.

Can polyester webbing be used for high-temperature applications?

Polyester has a moderate heat resistance but has limits. Its melting point is approximately 250-260°C (482-500°F). While it can withstand typical outdoor summer temperatures easily, it should not be used in direct, prolonged contact with high-heat sources like exhaust manifolds or welding equipment. For such applications, specialized high-temperature materials like aramid (Kevlar) are required. However, standard polyester webbing is perfectly suitable for the vast majority of automotive, outdoor, and industrial uses where ambient temperatures are within normal ranges.

Is recycled polyester (rPET) webbing as strong as virgin polyester?

Yes, high-quality recycled polyester (rPET) webbing can achieve strength and performance characteristics nearly identical to virgin polyester. The recycling process for PET (typically from bottles) breaks down the plastic to a polymer level, which is then re-polymerized and spun into new fibers. Advanced manufacturing techniques ensure these rPET fibers meet high tenacity standards. The resulting webbing offers the same excellent UV resistance, low stretch, and durability. The primary difference is the environmental benefit: rPET diverts plastic from landfills and requires less energy and crude oil to produce. When sourcing rPET webbing, it's important to partner with a manufacturer that uses certified recycled content and can provide consistent quality.

English

English  中文简体

中文简体