We are a national high-tech enterprise. At present, there are many kinds of self-woven and cooperatively processed fabrics, including microfiber warp-knitted towel cloth, weft-knitted towel cloth, coral fleece, etc.

- 1 What Defines Eco-Friendly Nylon Webbing Straps Today?

- 2 How Are Eco-Friendly Nylon Webbing Straps Manufactured?

- 3 Where Are Eco-Friendly Nylon Straps Used?

- 4 Are There Biodegradable Alternatives?

- 5 How to Evaluate Quality in Eco-Friendly Nylon Webbing?

- 6 FAQ

- 6.1 Are eco-friendly nylon webbing straps truly sustainable?

- 6.2 Are recycled nylon webbing straps strong enough for daily use?

- 6.3 Can eco-friendly nylon straps be used for bags?

- 6.4 How do low-impact dyed nylon straps differ from regular dyed straps?

- 6.5 Are biodegradable nylon alternatives available?

What Defines Eco-Friendly Nylon Webbing Straps Today?

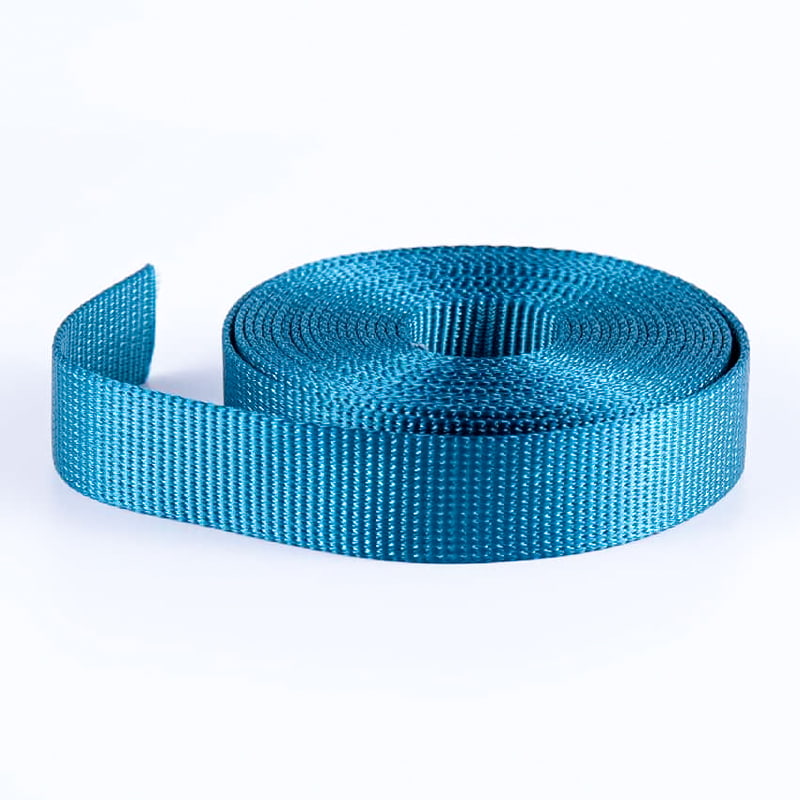

Eco-friendly nylon webbing straps are designed to meet rising global demands for sustainable materials, particularly in industries where durability and strength remain non-negotiable performance standards. These straps incorporate recycled inputs, cleaner dyeing processes, and lower-impact manufacturing technologies to reduce environmental pressure across their lifecycle. As textile and accessories markets shift toward greener solutions, understanding their material construction and eco-value becomes essential. One notable advancement is the increasing use of recycled nylon webbing straps, which help reduce petroleum reliance and minimize waste accumulation.

The concept of environmentally responsible nylon today goes beyond recycled content. It encompasses fiber engineering, energy-efficient production, stricter chemical management, and measurable sustainability indicators such as carbon footprint and water intensity. Manufacturers progressively adopt these innovations to align with global regulations and market expectations.

- Reduced environmental impact through recycled and low-impact materials.

- Enhanced structural strength suitable for high-wear applications.

- Better compliance with international sustainability guidelines.

How Modern Materials Support Sustainability

Sustainable nylon development focuses on reducing dependency on fossil-based resources while maintaining the mechanical integrity expected of high-performance webbing. The shift toward recycled feedstock significantly decreases industrial waste and introduces circularity to an industry traditionally dependent on virgin polymer production. Sustainable material choices are growing rapidly due to regulatory pressure, consumer demand, and technological improvements across the global textile supply chain.

Why Recycled Nylon Matters

The adoption of recycled nylon webbing straps supports waste diversion from landfills, limits microplastic generation, and reduces carbon emissions associated with virgin nylon production. These benefits have amplified their popularity in consumer goods, outdoor products, and industrial applications where sustainability is now part of brand identity and procurement requirements.

How Are Eco-Friendly Nylon Webbing Straps Manufactured?

The manufacturing process for eco-friendly nylon webbing straps integrates responsible material sourcing with cleaner production steps that minimize environmental harm. The goal is to maintain tensile strength, abrasion resistance, and longevity while reducing pollution and excessive energy consumption. Innovations such as low-impact dyed nylon webbing straps have further improved environmental profiles by lowering chemical discharge and water usage during coloration.

Raw Material Selection

Manufacturers source recycled nylon pellets, post-industrial waste, and regenerated fibers to meet environmental specifications without compromising material performance. These inputs undergo strict filtration and purification processes to ensure consistency in polymer quality before extrusion.

- Certified recycled nylon feedstock selection.

- Regulated polymer purification standards.

- Mechanical and chemical recycling integration.

Low-Impact Dyeing Technologies

Low-impact dyeing minimizes water usage, energy demand, and chemical discharge compared to traditional coloring processes. This technique is particularly important for producing low-impact dyed nylon webbing straps, which maintain vivid hues while complying with global chemical safety standards.

Process Flow Overview

Eco-friendly manufacturing models establish a cleaner production chain from polymer extrusion to weaving and finishing. These processes are designed to maximize operational efficiency while reducing carbon emissions, wastewater load, and hazardous chemical interaction.

Energy Use

Factories increasingly integrate energy-saving weaving systems, heat recovery units, and optimized motor control technology to ensure reduced electricity consumption during production.

Waste Reduction

Scrap reduction strategies involve real-time monitoring systems, updated loom calibration, and consistent maintenance schedules to prevent fabric defects and minimize waste generation.

Chemical Management

Chemical inventories follow strict regulatory compliance guidelines to ensure safe handling, correct disposal, and reduced environmental contamination. Manufacturers frequently transition toward safer auxiliaries and water-borne finishes for improved ecological performance.

Where Are Eco-Friendly Nylon Straps Used?

The versatility and performance consistency of eco-friendly nylon webbing straps allow them to support multiple industries where environmental responsibility is becoming a purchasing requirement. High strength, abrasion resistance, and structural stability make these straps a preferred material for various functional applications.

Bag & Luggage Industry

The demand for eco-friendly nylon straps for bags has increased as global brands seek reduced-impact materials that do not compromise strength or appearance. Modern bag manufacturers adopt these straps for handles, adjustable belts, backpack reinforcement, and travel accessories requiring durable yet environmentally responsible components.

- Strong tensile performance suitable for high-load bags.

- Stable colorfastness for fashion-oriented applications.

- Sustainable sourcing that aligns with brand requirements.

Outdoor Equipment & Gear

Outdoor goods require high structural resilience, weather resistance, and prolonged durability. Sustainable nylon webbing for outdoor gear ensures functional performance in harsh environments, including moisture, UV exposure, and abrasion-heavy scenarios.

Industry Application Comparison

The table below compares key application sectors and highlights performance-related expectations for webbing materials.

| Application | Performance Demand | Sustainability Level | Recommended Material |

| Bags | Medium Load / Abrasion | High | Recycled Nylon |

| Outdoor Gear | High Load / Harsh Weather | High | Sustainable Nylon |

| Pet Accessories | High Abrasion | Medium | Durable Eco Nylon |

Are There Biodegradable Alternatives?

Although nylon is not inherently biodegradable, new fiber innovation has introduced partially degradable polymer blends and plant-based webbing as market alternatives. When examining biodegradable nylon webbing alternatives, it is important to evaluate their tensile strength, moisture response, structural stability, and suitability for long-term use.

Comparison Between Traditional Nylon & Eco Materials

Performance varies significantly between traditional nylon, recycled nylon, and biodegradable fibers. Traditional nylon remains the strongest, while recycled nylon offers a balance of strength and sustainability. Biodegradable materials provide the lowest environmental footprint but may have limited durability depending on formula and intended use.

| Material Type | Strength | Durability | Sustainability |

| Traditional Nylon | High | High | Low |

| Recycled Nylon | Medium-High | High | High |

| Biodegradable Fiber | Medium | Medium | Very High |

How to Evaluate Quality in Eco-Friendly Nylon Webbing?

Evaluating quality involves analyzing weave density, tensile strength certification, colorfastness results, abrasion resistance, and compliance with sustainability standards. Buyers should prioritize materials demonstrating performance stability across temperature shifts, friction exposure, and prolonged tension.

- Check for tensile strength reports and durability testing.

- Review sustainability certification from recognized organizations.

- Confirm low-impact dyeing compliance for optimal eco-rating.

FAQ

Are eco-friendly nylon webbing straps truly sustainable?

Yes. Sustainability depends on recycled content percentage, dyeing efficiency, chemical management, and production energy use. High-quality eco-friendly nylon webbing straps integrate multiple environmental improvements while maintaining expected performance standards.

Are recycled nylon webbing straps strong enough for daily use?

Recycled nylon webbing straps retain high tensile strength and abrasion resistance comparable to many virgin nylon products. They are widely adopted in luggage, outdoor equipment, and pet accessories.

Can eco-friendly nylon straps be used for bags?

Yes. eco-friendly nylon straps for bags are specifically engineered to provide colorfastness, strength, and durability suitable for handbags, backpacks, and travel accessories.

How do low-impact dyed nylon straps differ from regular dyed straps?

Low-impact dyed nylon webbing straps are produced using reduced water, fewer chemicals, and energy-saving systems. They offer consistent color results while reducing environmental footprint.

Are biodegradable nylon alternatives available?

Some biodegradable nylon webbing alternatives exist, though their strength may vary. They are suitable for applications prioritizing environmental impact over maximum durability.

English

English  中文简体

中文简体